Publications

Book Chapters

Thermoactivated recycled cement. In: Sustainability of Concrete with synthetic and Recycled Aggregates, IntechOpen. ISBN: 978-1-83881-956-9, August 2021, 25p. Bogas JA, Carriço A, Real S

Influence of the treatment temperature on the microstructure and hydration behavior of thermoactivated recycled cement. In: Prime Archives in Material Science (e book): 3rd Edition. Editor: M. Iqbal Khan, Hyderabad, India: Vide Leaf, ISBN: 978-81-953047-9-0, May 2021, 32p. Real S, Carriço A, Bogas JA, Guedes M.

International Peer-Reviewed Articles

Durability of compressed earth blocks stabilised with recycled cement from concrete waste and incorporating construction and demolition waste. Construction and Building Materials, Vol 450, 138673, 2024. Cruz R, Bogas JA.

Eco-recycled cement’s effect on the microstructure and hygroscopic behaviour of compressed stabilised earth blocks. Journal of Building Engineering, Vol 95, 110227, 2024. Real S, Bogas JA, Cruz R, Gomes MG.

Thermal performance of compressed earth blocks stabilised with thermoactivated recycled cement. Energy and Buildings, Vol 314, 114288, 2024. Real S, Bogas JA, Cruz R, Gomes MG, Nabais M.

Water Resistance of Compressed Earth Blocks Stabilised with Thermoactivated Recycled Cement. Materials, Vol 17, 5617, 2024. Cruz, R.; Bogas, J.A.; Balboa, A.; Faria, P.

Recycled cement production energy consumption optimization. Sustainable Chemistry and Pharmacy, Vol 32, 101010, 2023. Sousa V, Bogas AJ, Real S, Meireles I, Carriço A.

Mechanical performance and shrinkage of compressed earth blocks stabilised with thermoactivated recycled cement. Journal of Building Engineering, Vol 79, 107892, 2023. Bogas J, Real S, Cruz R, Azevedo B.

Life Cycle Assessment of Thermoactivated Recycled Cement Production. Materials, 15, 6766, 2022. Real S, Sousa V, Meireles I., Bogas J, Carriço A.

Industrial production of recycled cement: energy consumption and carbon dioxide emission estimation. Environmental Science and Pollution Research, 2022. Sousa V, Bogas J, Real S, Meireles I.

Durability of concrete produced with recycled cement from waste concrete. Materials Proceedings Volume 58, Part 4, 2022. Bogas J, Carriço A, Real S.

Shrinkage and sorptivity of mortars with thermoactivated recycled cement. Construction and Building Materials, 333, 127392, 2022. Carriço A, Bogas J.A, Real S, Pereira MFC.

Hydration and phase development of recycled cement. Cement and Concrete Composites, Vol 127, 104405, 2022. Bogas JA, Real S, Carriço A, Abrantes JCC, Guedes M.

Durability performance of thermoactivated recycled cement concrete. Cement and Concrete Composites, Vol 124, 104270, 2021. Carriço A, Real S, Bogas JA.

Novel separation process for obtaining recycled cement and high-quality recycled sand from waste hardened concrete. Journal of Cleaner Production, Vol 309, 127375, 2021. Carriço A, Bogas A, Hu S, Real S, Pereira MFC.

Comparison of energy consumption and carbon emissions from clinker and recycled cement production. Journal of Cleaner Production, Vol 306, 127277, 2021. Sousa V, Bogas JA.

Mechanical Characterisation and Shrinkage of Thermoactivated Recycled Cement Concrete. Applied Sciences, Vol 11, 2454, 2021. Real S, Bogas J.A, Carriço A, Hu S.

Microstructure of thermoactivated recycled cement pastes. Cement and Concrete Research, Vol 138, 106226, 2020. Bogas JA, Carriço A, Tenza-Abril A.

Influence of the Treatment Temperature on the Microstructure and Hydration Behavior of Thermoactivated Recycled Cement. Materials, Vol 13(18), 3937, 2020. Real S, Bogas JA, Carriço A, Guedes M.

Mortars with thermo-activated recycled cement: fresh and mechanical characterization. Construction and Building Materials, Vol 256, 119502, 2020. Carriço A, Real S, Bogas JA, Pereira MFC.

Thermoactivated cementitious materials - a review. Construction and Building Materials, Vol 250, 118873, 2020.

Carriço A, Bogas JA, Guedes M.

Mechanical characterization of thermal activated low-carbon recycled cement mortars. Journal of Cleaner Production, Vol 218(1), 377-389, 2019. Bogas JA, Carriço A, Pereira MFC.

National Peer-Reviewed Articles

Durabilidade de blocos de terra comprimida estabilizados com ligantes recuperados a partir da fração cimentícia de resíduos de betão (Durability of compressed earth blocks stabilized with binders recovered from the cement fraction of concrete waste). Construção Magazine, 123, September/October 2024, ISSN 1645-1767: 22-26. Cruz R, Bogas JA, Real S, Rodrigues J.

Betões com cimento reciclado: caracterização mecânica e durabilidade (Concrete with recycled cement: mechanical characterisation and durability). Revista Portuguesa de Engenharia de Estruturas (RPEE), Accepted for publication in 2023, ID: 000147. Carriço A, Real S, Bogas JA.

Patent

Processo de separação dos componentes de resíduos de betão endurecido para obtenção de cimento reciclado (Process for separating the components of hardened concrete waste for producing recycling cement). Application No. 116130, priority date 24/02/2020, PCT/PT2021/050005. International patent WO 2021/173022, 02 September 2021. Bogas JA, Pereira MFC, Guedes AM, Carriço A, Hu S, Sousa R.

Dissertations

Estabilização de blocos de terra com ligantes recuperados a partir da fração cimentícia de resíduos de betão – Durabilidade (Stabilization of earth blocks with binders recovered from the cement fraction of concrete waste – Durability). Master’s Thesis, IST, Portugal, January 2024, Rodrigues J.

Caracterização mecânica de blocos de terra comprimida com incorporação de agregado e cimento reciclado (Mechanical characterization of compressed earth blocks with incorporation of aggregate and recycled cement). Master’s Thesis, IST, Portugal, June 2023, Nabais M.

Estabilização de blocos de terra com ligantes recuperados a partir da fração cimentícia de resíduos de betão – Caracterização mecânica e retração (Stabilization of earth blocks with binders recovered from the cement fraction of concrete waste – Mechanical characterization and shrinkage). Master’s Thesis, IST, Portugal, June 2023, Gonçalves D.

Caracterização mecânica, retracção e fluência de betões com cimento reciclado e agregados reciclados (Mechanical characterisation, shrinkage and creep of concrete with recycled cement and recycled aggregates) Master's Thesis, IST, Lisbon, Portugal, November 2022, Fortes P.

Separação dos constituintes do betão para a obtenção de argamassas 100% recicladas (Separation of concrete constituents towards 100% recycled mortars) Master's Thesis, IST, Lisbon, Portugal, September 2022, Cyrne C.

Caracterização mecânica de argamassas produzidas com clínquer reciclado (Characterisation of mortars with eco-efficient clinker). Master's Thesis, IST, Lisbon, Portugal, September 2022, Neves T.

Blocos de terra comprimida estabilizados com cimento reciclado (Compressed earthen blocks with recycled cement) Master's Thesis, IST, Lisbon, Portugal, September 2021, Azevedo B.

Durabilidade de betões produzidos com cimento reciclado (Durability of concrete with recycled cement). Master's Thesis, IST, Lisbon, Portugal, January 2021, Leal D.

Caracterização mecânica de betões produzidos com cimento reciclado (Mechanical characterisation of concrete with recycled cement). Master's Thesis, IST, Lisbon, Portugal, January 2021, Carvalho B.

Caracterização mecânica e retração em argamassas produzidas com cimento reciclado (Mechanical characterisation and shrinkage of mortars with recycled cement). Master's Thesis, IST, Lisbon, Portugal, September 2020, Bandeira J.

Caracterização de pastas produzidas com cimento reciclado sujeito a diferentes temperaturas de termoativação (Characterisation of pastes produced with recycled cement subjected to different thermoactivation temperatures). Master's Thesis, IST, Lisbon, Portugal, September 2020, Carvalho M.

Avaliação do ciclo de vida na produção de cimento reciclado (Life cycle assessment of recycled cement production). Master's Thesis, IST, Lisbon, Portugal, November 2019, Guedes T.

Separação dos constituintes do betão visando a obtenção de cimentos reciclados (Separation of concrete constituent towards recycled cement production). Master's Thesis, IST, Lisbon, Portugal, October 2019, Hu S.

Incorporação de adições em argamassas produzidas com cimento reciclado (Incorporation of mineral additions in mortars with recycled cement). Master's Thesis, IST, Lisbon, Portugal, October 2019, Gouveia M.

Argamassas com resíduos de materiais cimentícios de diferentes finuras (Mortars with cementitious residues of different fineness). Master's Thesis, IST, Lisbon, Portugal, May 2019, Neto G.

Book Chapters

THERMOACTIVATED RECYCLED CEMENT

Bogas J.A., Carriço A., Real S.

In: Sustainability of Concrete with synthetic and Recycled Aggregates, IntechOpen. ISBN: 978-1-83881-956-9, 2021

https://doi.org/10.5772/intechopen.98488

ABSTRACT:

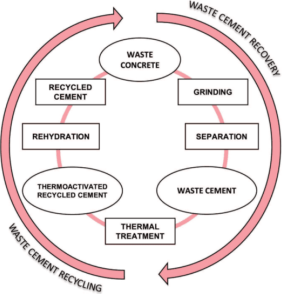

The cement industry is currently faced by the great challenge of reducing its vast carbon footprint, due to being the second highest industrial greenhouse gases (GHG) emitter. This value is expected to further increase, since cement production is foreseen to rise by about 20% until 2050. Therefore, more eco-efficient alternatives to ordinary Portland cement have been developed towards a sustainable concrete industry. This chapter presents some of the latest advances in low-carbon thermoactivated recycled cements (RC) obtained from old waste concrete, leading to a significant reduction of the GHG emissions, while also encouraging the valorization reuse of waste materials and the reduction of natural resource depletion. The manufacture and general performance of RC, including the main production issues, rehydration behavior and phase and microstructure development, as well as its incorporation in cement-based materials are discussed. Some of the most recent research, main challenges and future perspective of RC are addressed.

INFLUENCE OF THE TREATMENT TEMPERATURE ON THE MICROSTRUCTURE AND HYDRATION BEHAVIOR OF THERMOACTIVATED RECYCLED CEMENT

Real S., Carriço A., Bogas J.A., Guedes M.

Prime Archives in Material Science (e book): 3rd Edition. Hyderabad, India: Vide Leaf, ISBN: 978-81-953047-9-0, 2021

https://doi.org/10.37247/PAMS2ED.3.2021.13

ABSTRACT:

This paper aims to contribute to a better knowledge of the production and rehydration of thermo activated recycled cement (TRC) and its incorporation in cement based materials. To this end, the influence of different factors in the fresh and hardened properties of mortars with TRC was analysed, such as the water/binder ratio, the treatment temperature, incorporation percentage and particle fineness of TRC. Thermogravimetry, X-ray diffraction, isothermal calorimetry, scanning electron microscopy and 29Si nuclear magnetic resonance spectroscopy were carried out to better understand the hydration behaviour and microstructure development of TRC mortars. Optimal rehydration properties and strength development were obtained for recycled cement thermo activated at 600–800 ºC. Binders with CEM I 42.5R and 20, 50 and 100% TRC could be framed in the European normative strength classes 52.5, 42.5 and 32.5, respectively. The main obstacles that hinder the application of TRC are its low setting time and high water demand. However, the water demand and setting time were not significantly affected for up to 50% TRC incorporation. Moreover, the mechanical strength was little affected for up to 20% TRC replacement and was only 12% reduced for 50%TRC incorporation. Therefore, TRC proved to be a very promising supplementary cementitious material for cement replacement.

International Peer-Reviewed Articles

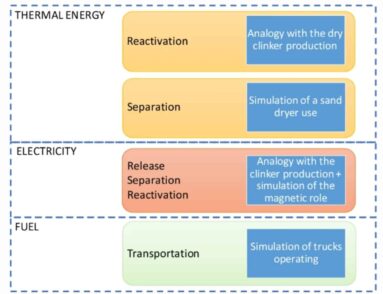

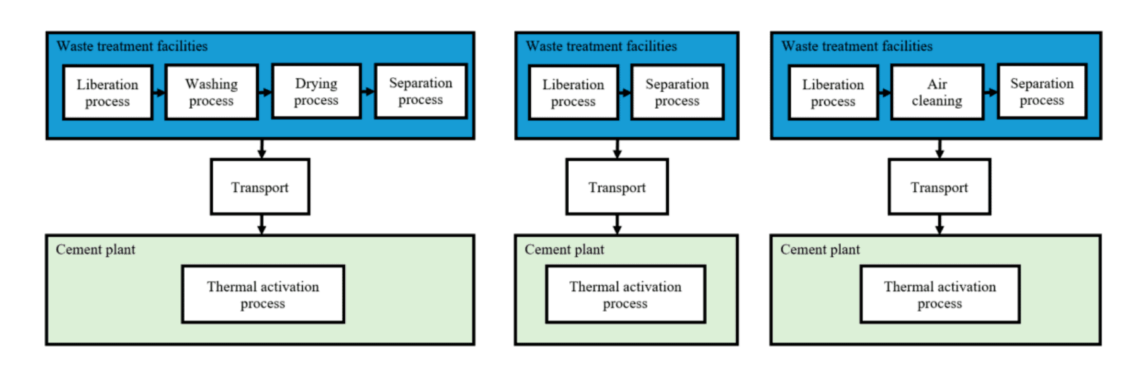

RECYCLED CEMENT PRODUCTION ENERGY CONSUMPTION OPTIMIZATION

Sousa V, Bogas AJ, Real S, Meireles I, Carriço A.

Sustainable Chemistry and Pharmacy, Vol 32, 101010, 2023

https://doi.org/10.1016/j.scp.2023.101010

ABSTRACT:

The concrete industry has made a firm commitment to reduce its excessive carbon footprint, essentially related to clinker production. Recycled cement (RC) from the thermoactivation of hardened cement waste at low temperature is a very promising approach, tackling the reduction of the clinker factor, the reuse of construction and demolition waste and the reduction of natural resources consumption. The implementation of RC at an industrial scale depends on the environmental and economic viability of its production. In this context, this paper aims to model the energy consumption and carbon emissions of RC production using a novel separation method recently patented by the authors. Three alternative processes were considered towards the best compromise between energy and separation efficiency: dry method (DM); wet method (WM); air method (AM). Results from this study indicate that the AM and DM led to a significant reduction of the energy consumption on RC production, compared to WM. Differences between AM and DM are not significant. The slightly higher energy consumption in AM is compensated by the higher purity of concrete waste derived cement fraction. Adopting the low-energy intensive AM or DM, the estimated energy consumption of RC was 30%-40% lower than that used in clinker production. Moreover, up to 80% savings in carbon emissions are estimated. The high low-carbon and low-embodied energy potential of RC is shown..

MECHANICAL CHARACTERIZATION OF THERMAL ACTIVATED LOW-CARBON RECYCLED CEMENT MORTARS

Bogas J.A., Carriço A., Pereira M.F.C.

Journal of Cleaner Production, Vol 218(1), 377-389, 2019

doi.org/10.1016/j.jclepro.2019.01.325

ABSTRACT:

In this study, low-carbon recycled cement (RC) was produced from thermally activated concrete and cement paste wastes and its incorporation in mortars, as cement replacement, was investigated. The calcination temperatures were defined based on thermogravimetric and X-ray diffraction analysis. Mortars were characterized in terms of their main fresh and mechanical properties (compressive and flexural strength, ultrasonic pulse velocity and dynamic modulus of elasticity). The influence of RC replacement ratio (20%, 50%, 75% and 100%), RC treatment temperature and RC fineness were analyzed. In all tested properties, RC from concrete waste showed significant lower efficiency than that from cement paste waste. The RC rehydration capacity was improved by increasing its fineness and preheating temperature. Mortars produced with 100% of 650 pre-heated RC were able to attain as high as 8.3 MPa of compressive strength at 28 days, corresponding to about 20% of that found in reference mortars without RC. In addition, mechanical properties were little affected by RC replacement ratios up to 20%. This study shows the efficient rehydration capacity of thermal activated RC and suggests its high potential for the construction industry.

THERMOACTIVATED CEMENTITIOUS MATERIALS – A REVIEW

Carriço A., Bogas J.A., Guedes M.

Construction Building Materials, Vol 250, 118873, 2020

https:doi.org/10.1016/j.conbuildmat.2020.118873

ABSTRACT:

Cementitious materials can regain hydraulic binding properties when thermally treated at high temperature, and this potential has been explored to obtain a new type of recycled binder. The current article examines the main phases involved in cement dehydration and rehydration and the dehydration kinetics. Main production issues, including reduced setting time and excessive water demand, and collected mechanical results are also described. The possibility to synergistically use thermoactivated cement with ordinary Portland cement and mineral additions to overcome some of the main current challenges reported in the literature is analysed. Overall, thermoactivated cements show great potential as a stepping stone towards fully recyclable concrete.

MORTARS WITH THERMO ACTIVATED RECYCLED CEMENT: FRESH AND MECHANICAL CHARACTERISATION

Carriço A., Real S., Bogas J.A., Pereira M.F.C.

Consrution Building Materials, Vol 256, 119502, 2020

https://doi.org/10.1016/j.conbuildmat.2020.119502

ABSTRACT:

This paper aims to contribute to a better knowledge of the production and rehydration of thermo activated recycled cement (TRC) and its incorporation in cement based materials. To this end, the influence of different factors in the fresh and hardened properties of mortars with TRC was analysed, such as the water/binder ratio, the treatment temperature, incorporation percentage and particle fineness of TRC. Thermogravimetry, X-ray diffraction, isothermal calorimetry, scanning electron microscopy and 29Si nuclear magnetic resonance spectroscopy were carried out to better understand the hydration behaviour and microstructure development of TRC mortars. Optimal rehydration properties and strength development were obtained for recycled cement thermo activated at 600–800 ºC. Binders with CEM I 42.5R and 20, 50 and 100% TRC could be framed in the European normative strength classes 52.5, 42.5 and 32.5, respectively. The main obstacles that hinder the application of TRC are its low setting time and high water demand. However, the water demand and setting time were not significantly affected for up to 50% TRC incorporation. Moreover, the mechanical strength was little affected for up to 20% TRC replacement and was only 12% reduced for 50%TRC incorporation. Therefore, TRC proved to be a very promising supplementary cementitious material for cement replacement.

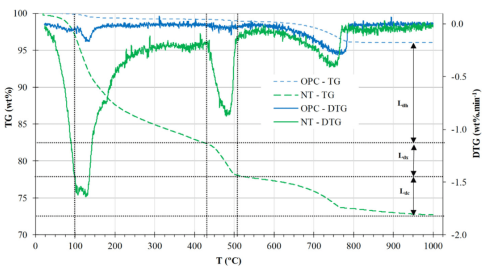

INFLUENCE OF THE TREATMENT TEMPERATURE ON THE MICROSTRUCTURE AND HYDRATION BEHAVIOR OF THERMOACTIVATED RECYCLED CEMENT

Real S., Bogas J.A., Carriço A., Guedes M.

Materials Journal, Vol 13(18), 3937, 2020

https://doi.org/10.3390/ma13183937

ABSTRACT:

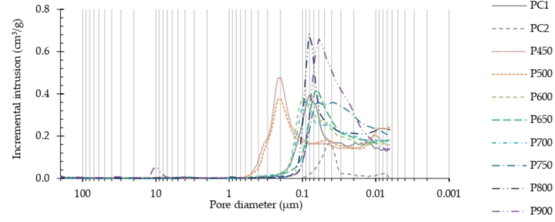

This paper intends to contribute to a better knowledge of the production and rehydration of thermoactivated recycled cement and its incorporation in cement-based materials. To this end, the influence of the treatment temperature on the properties of recycled cements and recycled cement pastes was assessed by means of a wide array of tests. Anhydrous recycled cement as well as the resulting pastes were characterized through density and particle size, water demand and setting time, thermogravimetry, X-ray diffraction, field emission gun scanning electron microscopy, isothermal calorimetry, 29Si nuclear magnetic resonance spectroscopy, flowability, mechanical strength, mercury intrusion porosimetry and scanning electron microscopy. The treatment temperature had a significant influence on the dehydration and hydration of recycled cement, essentially resulting in the formation of C2S polymorphs of varying reactivity, which led to pastes of different fresh and hardened behaviors. The high water demand and the pre-hydration of recycled cement resulted in high setting times and low compressive strengths. The highest mechanical strength was obtained for a treatment temperature of 650 ºC.

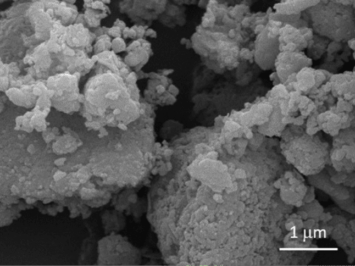

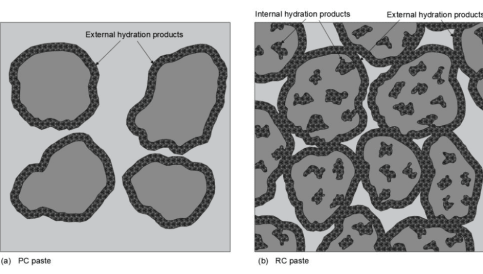

MICROSTRUCTURE OF THERMOACTIVATED RECYCLED CEMENT PASTES

Bogas J.A., Carriço A., Tenza-Abril A.

Cement and Concrete Research, Vol 138, 106226, 2020

https://doi.org/10.1016/j.cemconres.2020.106226

ABSTRACT:

This paper focuses on the microstructural characterisation of pastes produced with thermoactivated recycled cement (RC). To this end, a comprehensive experimental program combining thermogravimetry (TG), X-ray diffraction (XRD), isothermal calorimetry, scanning electron microscopy (SEM), quantitative backscattering electron (BSE) imaging, mercury intrusion porosimetry (MIP), nitrogen adsorption and mechanical tests, was performed. The hydration and microstructure evolution of RC was monitored over time, between 8 h and 28 days, and compared against ordinary Portland cement (OPC) pastes of equal w/b or workability. RC showed effective rehydration with formation of C-S-H, AFm, AFt and carbonation phases since very early ages, developing high initial reactivity, with lower coarse porosity and higher volume of hydration products than OPC pastes of equal w/b up to 3 days. The RC paste is defined by two sub-structures composed by the outer hydrated phases of bulk paste and the inner RC hydration products, which affect its fresh and hardened behaviour.

MECHANICAL CHARACTERISATION AND SHRINKAGE OF THERMOACTIVATED RECYCLED CEMENT CONCRETE

Real S., Bogas J.A., Carriço A., Hu S.

Applied Sciences, Vol 11, 2454, 2021

https://doi.org/10.3390/app11062454

ABSTRACT:

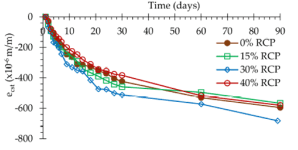

This paper investigates the mechanical and shrinkage behaviour of concrete with recycled cement (RC) thermoactivated from waste cement paste and waste concrete. Overall, compared to ordinary Portland cement (OPC), for the same water/binder ratio, the mechanical strength and ultrasonic pulse velocity were not significantly influenced by the incorporation of RC. The elasticity modulus decreased with the addition of RC and the shrinkage tended to increase at high RC content. The incorporation of up to 15% RC allowed the production of workable concrete with identical shrinkage and similar to higher mechanical strength than concrete with only OPC. RC proved to be a very promising more eco-efficient supplementary cementitious material.

COMPARISON OF ENERGY CONSUMPTION AND CARBON EMISSIONS FROM CLINKER AND RECYCLED CEMENT PRODUCTION

Sousa V., Bogas J.A.

Journal of Cleaner Production, Vol 306, 127277, 2021

https://doi.org/10.1016/j.jclepro.2021.127277

ABSTRACT:

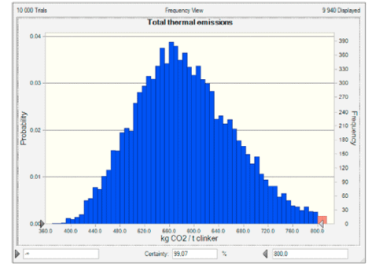

The cement industry is presently facing the demanding challenge of reducing its large amount of carbon emissions in order to meet the targets set to fight climate changes. One recent, and very promising, approach to reduce the carbon footprint is the production of more eco-efficient recycled cement from cement-based waste materials. This study aims at comparing the difference in terms of energy consumption and carbon dioxide emissions between recycled cement and conventional clinker production. In a conservative scenario, the estimated carbon dioxide emissions from recycling cement was as low as 58%-74% of the clinker production. From the sensibility analysis, it was found that the most influencing factors for the carbon emissions from the recycled cement production are: i) the waste cement water content; ii) the fraction of cement paste on waste material; and iii) the dryer energy intensity. The main drawback of the recycled cement production process is the pretreatment stage related with washing and drying of waste materials. The carbon dioxide emissions from recycled cement production can be potentially reduced to only 13% of the emissions from clinker production, if these pretreatment stages are avoided by developing a dry process.

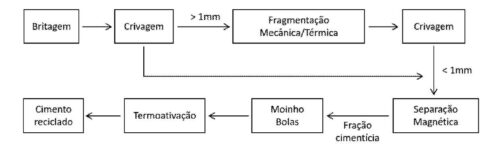

NOVEL SEPARATION PROCESS FOR OBTAINING RECYCLED CEMENT AND HIGH-QUALITY RECYCLED SAND FROM WASTE HARDENED CONCRETE

Carriço A., Bogas A., Hu S., Real S., Pereira M.F.C.

Journal of Cleaner Production, Vol 309, 127375, 2021

https://doi.org/10.1016/j.jclepro.2021.127375

ABSTRACT:

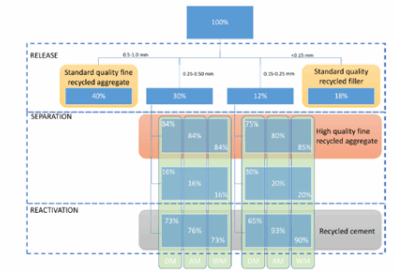

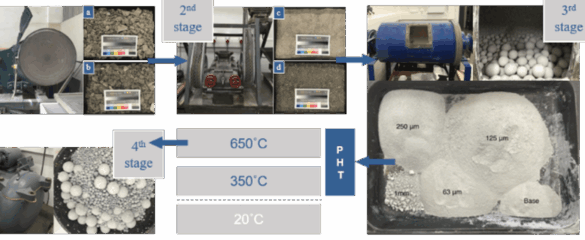

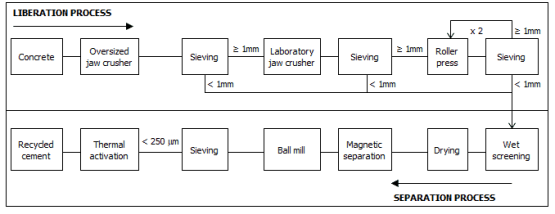

Separation is a fundamental step for concrete recycling, enabling not only the achievement of reliable and cleaner recycled aggregates but also the better re-use of the remaining concrete constituents. Recently, a new hydraulic binder produced from the hydrated cement paste contained in waste concrete, which is associated with lower processing temperatures and carbon dioxide emissions, has gained momentum in the history of concrete recycling. However, a decisive turning point for its application lies in the successful individualisation of the cement paste and aggregate initially contained in concrete debris. This paper describes a new patented method involving a mechanical comminution stage and a high-intensity magnetic separation process to obtain the cementitious fraction in concrete and retrieve cleaner fine aggregate. The efficiency of the proposed method was assessed through image analysis, thermogravimetry, X-ray diffraction and acid attack. In addition, cement pastes produced with the obtained recycled cement after thermal activation were characterised in terms of mechanical strength. Findings suggest that the proposed method effectively separated the main concrete constituents, especially when the waste material was reduced to the size range 150–500 μm. It was possible to obtain a recycled binder at the current laboratory scale with up to about 80% cement content by weight (nearly 90% in volume). Furthermore, a cleaner recycled fine aggregate, with minimal cement paste contamination, as low as less than 3 wt%, was also obtained. The mechanical strength of pastes with recycled cement retrieved from waste concrete was about 70% of that of reference pastes of equal water/binder produced with recycled cement from non-contaminated waste cement pastes.

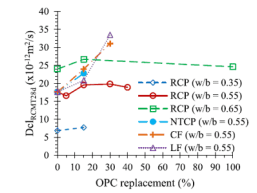

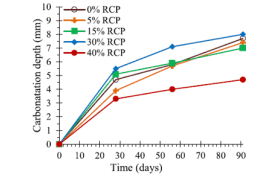

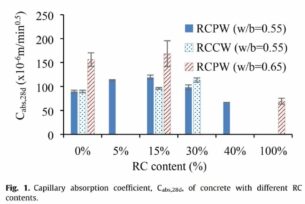

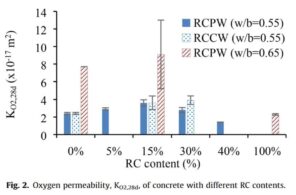

DURABILITY PERFORMANCE OF THERMOACTIVATED RECYCLED CEMENT CONCRETE

Carriço A., Real S., Bogas A.

Cement and Concrete Composites, Vol 124, 104270, 2021

https://doi.org/10.1016/j.cemconcomp. 2021.104270

ABSTRACT:

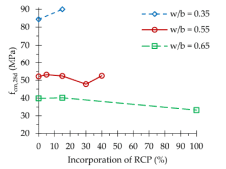

This paper characterises the durability of concrete produced with thermoactivated recycled cement (RC) obtained from waste cement paste or the cementitious fraction of waste concrete. The durability of concrete produced with 5–100% RC and water/binder ratios of 0.35–0.65 was assessed through capillary absorption, oxygen permeability, rapid chloride migration and carbonation resistance tests. Overall, RC thermoactivated at 650 ºC showed high rehydration capacity and effectively improved the durability properties of concrete compared to the same non-treated waste materials. Moreover, concretes with up to 100% RC reached comparable durability to that of reference concretes of equal w/b.

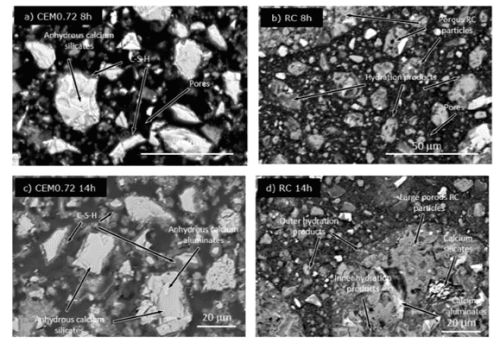

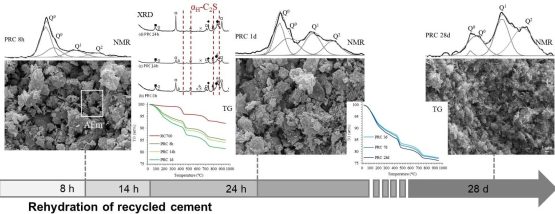

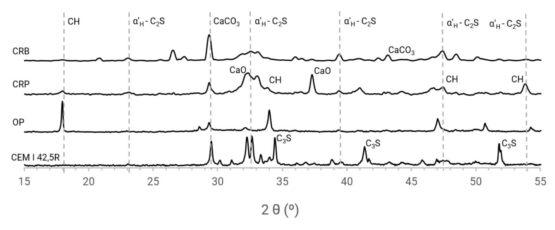

HYDRATION AND PHASE DEVELOPMENT OF RECYCLED CEMENT

Bogas J.A., Real S., Carriço A., Abrantes J.C.C., Guedes M.

Cement and Concrete Composites, Vol 127, 104405, 2022

https://doi.org/10.1016/j.cemconcomp.2022.104405

ABSTRACT:

This paper provides an in-depth analysis of the rehydration behaviour of recycled cement, obtained from thermal activation of waste cementitious materials. Phases’ early age composition and development in pastes produced with recycled cement were followed from 8 h to 28 days and compared to those of Portland cement paste of similar composition. Characterisation was carried out using isothermal calorimetry, thermogravimetry, X-ray diffraction with Rietveld analysis, nuclear magnetic resonance spectroscopy, scanning electron microscopy and mechanical testing. The most significant hydration rate of recycled cement occurred after 24 h; corresponding calorimetric curves revealed a longer induction period than Portland cement pastes and a late acceleration peak after 30 h of hydration. Thermal analysis and microscopy observation showed that AFm phases in recycled cement paste developed at as early as 8 h. The α′ H–C2S polymorph was identified through X-ray diffraction as the main phase present in anhydrous recycled cement. Rietveld analysis indicated a more significant reaction rate of this polymorph between 1 and 3 days, similarly to C3S in Portland cement paste at 28 days. The lower amount of the less reactive β-C2S phase in recycled cement paste than in Portland cement paste appears to have led to slightly higher degree of hydration of the former at 28 days. However, the total volume of long-term hydrates was lower in recycled cement paste. A C/S ratio of 1.73 was estimated for α′ H–C2S and nuclear magnetic resonance suggest that a similar type of C–S–H was formed in both pastes.

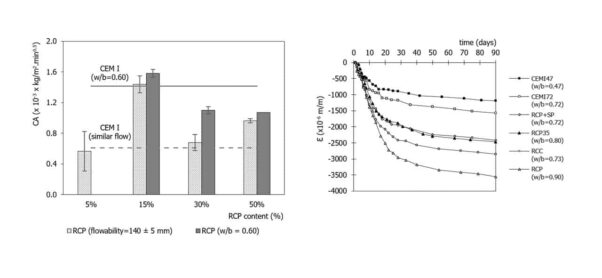

SHRINKAGE AND SORPTIVITY OF MORTARS WITH THERMOACTIVATED RECYCLED CEMENT

Carriço A.,Bogas J.A., Real S., Pereira M.F.C.

Construction and Building Materials, Vol 333, 127392, 2022

https://doi.org/10.1016/j.conbuildmat.2022.127392

ABSTRACT:

This study aims to characterise the shrinkage and sorptivity behaviour of mortars produced with thermally activated recycled cement (RC) sourced from reference waste cement paste (RCP) or from the cementitious fraction of old concrete (RCC), the latter following a new patented method. Ordinary Portland Cement (OPC) was replaced with 5-100% RC, in mortars of similar consistency or equal water/binder (w/b). The influence of RC particle size and source material composition were also assessed. Moreover, selected mortars were produced with partial incorporation of fly ash to explore the high alkalinity of RC. Compared to OPC mortars of equal w/b, the compressive strength was not significantly altered for up to 15% RCP and reduced less than 25% for up to 100% RCP. For similar flowability, the water absorption and shrinkage were higher in RC mortars, following the necessary increase of the w/b. However, for fixed w/b, RC mortars presented a more refined interparticle porosity, and the coefficient of absorption decreased with RC content. Shrinkage consistently increased with RC content due to the refined interparticle microstructure, higher water demand and lower particle hardness of RC. Nevertheless, the 90 days shrinkage increased less than 17% for up to 50% RCP. Overall, RC's high potential was shown as an active supplementary cementitious material, with a negligible influence on shrinkage for up to 50% replacement.

Durability of concrete produced with recycled cement from waste concrete

Bogas J.A., Carriço A., Real S.

Materials Proceedings Volume 58, Part 4, 2022

https://doi.org/10.1016/j.matpr.2022.01.280

ABSTRACT:

In the present study, concretes produced with recycled cement (RC) obtained from the thermoactivation of concrete waste (RCCW) or laboratory cement paste (RCPW) were analysed in terms of some of their main transport properties (capillary absorption, oxygen permeability) and carbonation and chloride penetration resistance. Recycled cement was incorporated at various percentages, between 5% and 100%, taking into account concretes of different w/b. RCCW was obtained from an innovative process of concrete waste separation recently patented by the authors, allowing the retrievement of cement waste with almost 90 vol% purity. RCPW and RCCW showed high rehydration capacity and concrete produced with them reached comparable durability to that of reference ordinary Portland cement (OPC) concrete. For up to 15% RCCW replacement the concrete durability was not significantly affected and the cement retrievement from concrete waste was very effective. Overall, RCPW and RCCW actively contributed to the densification of the microstructure and the improvement of concrete durability. The recycled cement, as obtained in the present study, showed high potential to be used as an eco-efficient clinker substitute.

Industrial production of recycled cement: energy consumption and carbon dioxide emission estimation

Sousa V., Bogas J., Real S., Meireles I.

Environmental Science Pollution Research, 2022

https://doi.org/10.1007/s11356-022-20887-7

ABSTRACT:

The urge to reduce greenhouse gas emissions, in particular carbon dioxide, is a global problem, not only in spatial terms but also in terms of the scope of activities and sectors involved. Nevertheless, some sectors/industries are more critical due to their overall contribution to the problem, which is the case of the Portland cement industry. The present research estimates the energy consumption and carbon emissions associated with a novel process for producing cement by recycling used concrete and mortars. The novel process assessed resorts to the magnetic separation of the cement paste from the aggregates, followed by the thermal reactivation of the cement paste. Comparing the recycled cement production with the clinker production, higher energy consumption (over 9000 MJ/t compared with roughly 4000 MJ/t for Portland cement) and lower carbon dioxide emissions (average 730 kg CO2/t compared with more than 800 kg CO2/t for Portland cement) were estimated. However, the potential benefits in an industrial application are potentially much higher with the optimization of the production process. In particular, improvements in the washing and drying of the material prior to the magnetic separation will be critical since most of the energy is consumed in the process of drying.

LIFE CYCLE ASSESSMENT OF THERMOACTIVATED RECYCLED CEMENT PRODUCTION

Real S., Sousa V., Meireles I., Bogas J.A., Carriço A.

Materials, 15 (19), 6766, 2022

https://doi.org/10.3390/ma15196766

ABSTRACT:

The urgent need to tackle the effects of global warming has led to a worldwide compromise and ever-more demanding regulations. In this respect, as an important greenhouse gas emitter, the cement industry has to implement major changes in its production processes to achieve future goals. In this perspective, low-carbon eco-efficient cement, such as the thermoactivated recycled cement from concrete waste (RCC), seem to be a promising alternative to current carbon-intensive binders, such as ordinary Portland cement (OPC). This study aimed to demonstrate the potential contribution of RCC to the reduction in the environmental impacts of the cement industry, by means of a comparative life cycle assessment of three production methods of this binder (wet (WM), dry (DM) and air clean (ACM) methods) and OPC. Overall, RCC WM did not turn out to be a good alternative to OPC, essentially owing to the amount of fuel and electricity required for washing and drying the particles before the magnetic separation. On the other hand, RCC DM and RCC ACM proved to be promising alternatives to RCC WM and OPC, with a relevant reduction in all impact categories.

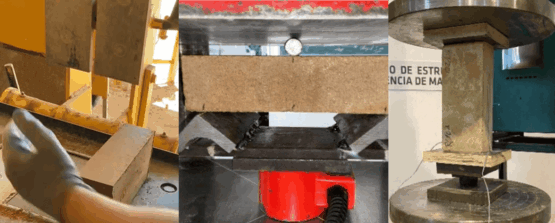

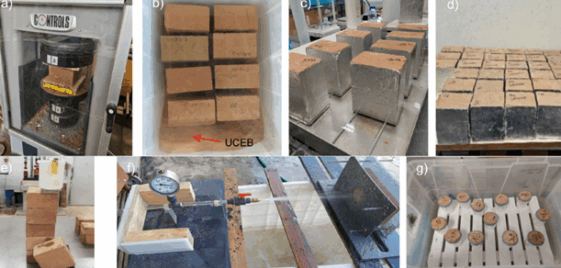

MECHANICAL PERFORMANCE AND SHRINKAGE OF COMPRESSED EARTH BLOCKS STABILISED WITH THERMOACTIVATED RECYCLED CEMENT

Bogas J.A., Real S., Cruz R., Azevedo B.

Journal of Building Engineering, Vol 79, 107892, 2023

ABSTRACT:

This paper explores the production and mechanical characterisation of compressed earth blocks (CEB) stabilised with thermoactivated recycled cement (RC) as a more sustainable alternative to ordinary Portland cement (OPC). CEB with 5-10% stabiliser, considering different OPC replacement percentages with RC, were characterised in terms of their main physical and mechanical properties in different moisture conditions.

RC revealed high rehydration and stabilisation capacity, significantly improving the mechanical strength of CEB. The mechanical strength improved as much as twice after RC stabilisation and new eco efficient blocks met the normative requirements. The mechanical strength was little affected up to 50%OPC replacement. RC showed high potential as an eco-efficient alternative to OPC in earth stabilisation.

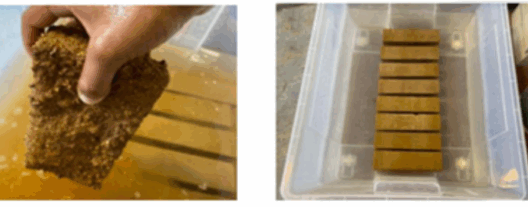

WATER RESISTANCE OF COMPRESSED EARTH BLOCKS STABILISED WITH THERMOACTIVATED RECYCLED CEMENT

Cruz, R.; Bogas, J.A.; Balboa, A.; Faria, P

Materials, Vol 17, 5617, 2024

ABSTRACT:

Low water resistance is the main shortcoming of unfired earth materials, requiring chemical stabilisation for some durable applications. Ordinary Portland cement (PC) is an efficient stabiliser, but it goes against the ecological and sustainable nature of earth construction. This study explores the use of low-carbon thermoactivated recycled cement (RC) obtained from old cement waste as a new eco-efficient alternative to PC in the stabilisation of compressed earth blocks (CEBs). The objective is to improve the durability of the CEB masonry even when applied in direct contact with water, without compromising its eco-efficiency. The water resistance of the CEBs with 0% (unstabilised) and 5% and 10% (wt. of earth) stabiliser and partial to total replacement of PC with RC (0, 20, 50, 100% wt.) was evaluated in terms of compressive strength under different moisture contents, immersion and capillary water absorption, low-pressure water absorption, water permeability and water erosion. Low absorption and high resistance to water erosion were achieved in stabilised CEBs, regardless of the type of cement used. The incorporation of RC increased the total porosity and water absorption of the CEBs compared to PC, but significantly improved the water resistance of the unstabilised blocks. The eco-friendlier RC proved to be a promising alternative to PC stabilisation.

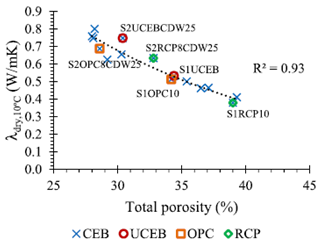

THERMAL PERFORMANCE OF COMPRESSED EARTH BLOCKS STABILISED WITH THERMOACTIVATED RECYCLED CEMENT

Real S, Bogas JA, Cruz R, Gomes MG, Nabais M

Energy and Buildings, Vol 314, 114288, 2024

ABSTRACT:

This study aimed to characterise the thermal behaviour of more eco-efficient compressed earth blocks (CEB) simultaneously stabilised with thermoactivated recycled cement (RCP) and with incorporation of construction and demolition waste (CDW). To this end, the thermal conductivity, specific heat capacity and thermal diffusivity were determined for a wide range of CEB, with compressive strengths of 2–10 MPa, and varying types of soil, types and amounts of stabiliser and CDW contents. The thermal performance of CEB was governed by their microstructure, which was characterised by mercury intrusion porosimetry and N2 adsorption analysis. The thermal properties were essentially influenced by their total porosity, and to less extent, their porosity distribution, rather than their composition. The influence of moisture content on the thermal conductivity of CEB also depended on the porosity distribution of the CEB. Overall, even for similar total porosity and mechanical strength, the replacement of cement with RCP or the incorporation of CDW tended to improve the thermal performance of CEB

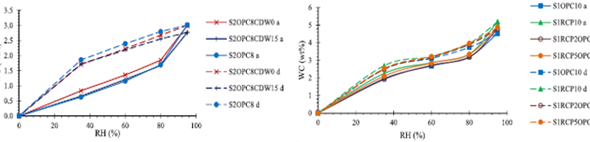

ECO-RECYCLED CEMENT’S EFFECT ON THE MICROSTRUCTURE AND HYGROSCOPIC BEHAVIOUR OF COMPRESSED STABILISED EARTH BLOCKS

Real S, Bogas JA, Cruz R, Gomes MG

Journal of Building Engineering, Vol 95, 110227, 2024

ABSTRACT:

Recycled cement (RCP) retrieved from old cement waste aims to replace carbon-intensive ordinary Portland cement (OPC) in earth stabilisation, improving the mechanical performance and durability of earth construction, without significantly compromising its ecological character and thermophysical properties. This study analyses the microstructure and hygroscopic behaviour of compressed earth blocks (CEB) stabilised with RC. In addition, soil was partially replaced with construction and demolition waste (CDW) to further improve the CEB sustainability. To this end, the sorption-desorption isothermal behaviour of CEB with different soils, types and contents of stabiliser (0–10 % RCP or OPC), and varying percentage replacements of OPC with RCP (20, 50, 100 %) or soil with CDW (0, 15, 25 %) was analysed and related to their microstructure, which was characterised in terms of scanning electron microscopy, mercury intrusion porosimetry and nitrogen adsorption analysis. Unstabilised and OPC CEB were considered for comparison purposes. The microstructure of CEB was refined after RCP stabilisation, which influenced their hygroscopicity and adsorption-desorption hysteresis. Depending on the clay content of the soil, stabilisation reduced or increased the hygroscopic capacity of CEB. After stabilisation, the water adsorption decreased up to 25 % in CEB with clayey soil and increased up to 22 % in CEB with sandy soil. However, the hygroscopic behaviour was not significantly affected by the type of stabiliser. The substitution of OPC with RCP increased the volume of water adsorption up to 3 %, due to its slightly finer porosity. RCP has proven to be effective as an earth stabiliser, leading to CEB with adsorption-desorption properties similar to those of OPC CEB.

DURABILITY OF COMPRESSED EARTH BLOCKS STABILISED WITH RECYCLED CEMENT FROM CONCRETE WASTE AND INCORPORATING CONSTRUCTION AND DEMOLITION WASTE

Cruz R, Bogas JA

Construction and Building Materials, Vol 450, 138673, 2024

ABSTRACT:

Chemical stabilisation is essential to reduce the high water susceptibility of compressed earth blocks (CEB), the main shortcoming of earthen construction. However, alternative low-carbon stabilisers to Portland cement (PC) are needed to keep the low embodied energy of CEB, without significantly affecting their performance. This study explores the innovative use of recycled cement (RC), recovered from old cement waste, in the stabilisation of water-resistant CEB. The aim is to analyse the durability behaviour of CEB stabilised with RC and compare it with that of unstabilised CEB and reference CEB with PC. To this end, CEB with different stabiliser content (0, 4, 8 %), and partial to total replacement of PC with RC (20, 50, 100 %) were characterised in terms of their microstructure and main mechanical and durability properties, namely compressive strength, water absorption, drying rate, water erosion and water vapour permeability. In addition, soil was partly replaced with up to 25 % construction and demolition waste (CDW) to further improve the eco-efficiency of CEB. The CEB performance was essentially affected by the stabiliser amount and water content. CEB with PC had higher mechanical strength and lower water absorption than those with RC, due to their lower water demand. However, for the same water content, RC CEB performed similarly to PC CEB. Moreover, the water erosion and vapor permeability were not significantly affected by the type of binder. The CEB performance was affected by its microstructure, which tended to be more refined in RC CEB. In addition, the RC stabilisation almost triplicated the mechanical strength and significantly improved the water resistance of unstabilised CEB, remaining undamaged after immersion or severe water erosion. Durability was little affected by replacing up to 25 % of the soil with CDW. The simultaneous incorporation of just 4 % RC and up to 25 % CDW has made it possible to produce more eco-efficient CEB, while ensuring high water resistance.

National Peer-Reviewed Articles

Betões com cimento reciclado: caracterização mecânica e durabilidade

Carriço A, Real S, Bogas JA.

Revista Portuguesa de Engenharia de Estruturas (RPEE), série III, 21, March 2023, ISSN 2183-8488: 25-34.

ABSTRACT:

O cimento reciclado (CR) é um novo ligante de baixo carbono que explora a reidratação dos compostos do cimento, através da termoativação de resíduos cimentícios. Neste estudo, caracteriza-se o comportamento no estado fresco e endurecido (resistência à compressão, carbonatação, penetração de cloretos e retração) de betões estruturais mais eco-eficientes produzidos com até 30% de substituição de cimento por CR. O CR foi obtido de resíduos de pasta (CRP) ou betão (CRB), seguindo um novo método de separação recentemente patenteado. O desempenho do CR foi confrontado com o de adições correntes (cinzas, fíler calcário). Verificou-se que até 15% CR, a resistência mecânica e a durabilidade não foram afetadas. Para percentagens superiores, o desempenho foi semelhante a ligeiramente inferior. Até 15% de incorporação, os betões com CRP e CRB apresentaram idêntico desempenho. O CR foi mais eficiente do que as restantes adições analisadas, posicionando-se como um material de substituição de grande potencial.

DURABILIDADE DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM LIGANTES RECUPERADOS A PARTIR DA FRAÇÃO CIMENTÍCIA DE RESÍDUOS DE BETÃO

Cruz R, Bogas JA, Real S, Rodrigues J

Construção Magazine, 123, September/October 2024, ISSN 1645-1767: 22-26

ABSTRACT:

O trabalho experimental visou avaliar a durabilidade de blocos de terra comprimida (BTC) estabilizados com materiais cimentícios, através da análise da massa volúmica, resistência à compressão, absorção por imersão, absorção capilar e erosão acelerada. Os blocos foram produzidos substituindo progressivamente o cimento Portland (CP) por cimento reciclado de pasta (CRP) ou betão (CRB) e o solo por resíduos de construção e demolição (RCD). O desempenho dos BTC dependeu essencialmente do teor de ligante, teor em água e da compactação. Os BTC estabilizados com CP apresentaram melhor desempenho mecânico e menor absorção de água devido à sua maior compactação. No entanto, a erosão não dependeu do tipo de ligante. Os BTC não estabilizados desintegraram-se em contato com água, enquanto os BTC estabilizados com CRP ou CRB resistiram à imersão, alcançaram uma alta resistência à erosão e triplicaram a resistência à compressão. Concluiu-se que estes ligantes são uma alternativa viável ao CP. A incorporação de até 25 % RCD não afetou significativamente o desempenho dos BTC, oferecendo uma solução mais sustentável.

Patents

Process for separating the components of hardened concrete waste for producing recycling cement

Bogas JA, Pereira MFC, Guedes AM, Carriço A, Hu S, Sousa R.

International patent WO 2021/173022, 02 September 2021

https://doi.org/10.5772/intechopen.98488

ABSTRACT:

The present invention falls within the field of building materials and relates to a process for separating the components of hardened concrete for the purpose of extracting the cement fraction for use thereof in the production of heat activated recycled cement, said process involving the essential steps of: a) crushing the concrete waste; b) screening the crushed material and separating the material with a size of less than about 1 mm; c) fragmenting the material with a size of more than 1 mm; d) screening the material with a size of less than 1 mm into various grain size fractions; e) high-intensity magnetic separation of the material; f) grinding the cement fraction resulting from the magnetic separation of the previous step to a size that allows efficient heat activation thereof; and g) obtaining a heat activated recycled cement.