Conferences

International conferences

Mechanical strength and shrinkage of earth mortars stabilised with recycled cement. 5º Congresso luso-brasileiro de materiais de construção sustentáveis (CLBMCS 2024), Lisbon, IST, 6-8 November 2024. Balboa A, Bogas JA, Tenza-Abril A, Pérez-Hernández Y.

Comportamento higroscópico de blocos de terra comprimida estabilizados com cimento reciclado termoativado (Hygroscopic behaviour of compressed earth blocks stabilised with thermoactivated recycled cement). 5º Congresso luso-brasileiro de materiais de construção sustentáveis (CLBMCS 2024), Lisbon, IST, 6-8 November 2024. Real S, Bogas JA, Cruz R, Gomes M.

Caracterização mecânica e retração de blocos de terra comprimida estabilizados com ligantes recuperados a partir da fração cimentícia de resíduos de betão (Mechanical characterisation and shrinkage of compressed earth blocks stabilised with binders recovered from the cement fraction of concrete waste). 5º Congresso luso-brasileiro de materiais de construção sustentáveis (CLBMCS 2024), Lisbon, IST, 6-8 November 2024. Cruz R, Bogas JA, Nabais M, Real S.

Desempenho térmico de blocos de terra comprimida estabilizados com cimento reciclado termoativado (Thermal performance of compressed earth blocks stabilised with heat-activated recycled cement). 5º Congresso luso-brasileiro de materiais de construção sustentáveis (CLBMCS 2024), Lisbon, IST, 6-8 November 2024. Real S, Bogas JA, Cruz R, Nabais M, Gomes M.

Durabilidade de blocos de terra comprimida estabilizados com ligantes recuperados a partir da fração cimentícia de resíduos de betão (Durability of compressed earth blocks stabilised with binders recovered from the cement fraction of concrete waste). 5º Congresso luso-brasileiro de materiais de construção sustentáveis (CLBMCS 2024), Lisbon, IST, 6-8 November 2024. Cruz R, Bogas JA, Real S, Rodrigues J.

Resultados preliminares de morteros de tierra estabilizados con cemento reciclado: caracterización en estado fresco y resistencia mecánica (Preliminary results of earth mortars stabilised with recycled cement: characterisation in fresh state and mechanical resistance). XVII congresso Nacional de Materiales (CNMAT 2024), Universidad de Málaga, 25-28 June 2024, Málaga, Spain, Balboa A, Bogas JA, Tenza-Abril A, Pérez-Hernández Y.

Estudio de la absorción capilar y retracción por secado en morteros de tierra estabilizados con cemento reciclado (Study of capillary absorption and drying shrinkage in earth mortars stabilized with recycled cement). XVII congresso Nacional de Materiales (CNMAT 2024), Universidad de Málaga, 25-28 June 2024, Málaga, Spain, Balboa A, Bogas JA, Tenza-Abril A, Pérez-Hernández Y.

Water resistance of recycled cement compressed earth blocks. 10th International Conference on Sustainable Solid Waste Management (CHANIA 2023), 21-24 June 2023, Chania, Crete, Greece, Bogas JA, Cruz R, Azevedo B, Balboa A, Sousa V.

Thermal conductivity of compressed earth blocks produced with recycled cement. 10th International Conference on Sustainable Solid Waste Management (CHANIA 2023), 21-24 June 2023, Chania, Crete, Greece, Gomes MG, Bogas JA, Real S, Cruz R

Physical and Mechanical strength characterization of compressed earth blocks produced with recycled cement. 10th International Conference on Sustainable Solid Waste Management (CHANIA 2023), 21-24 June 2023, Chania, Crete, Greece, Bogas JA, Cruz R, Azevedo B, Real S, Gomes MG.

Towards fully-recycled net zero high sustainable green concrete (Invited Talk). Energy-Climate-Environment Conference ECE 2022 – Seminar “CCS-CCU technology for carbon footprint reduction using bio-adsorbents”, Czetochowa, Poland, September 14-16 2022, Bogas JA.

Eco-efficient green mortars with recycled cement – Mechanical strength and volumetric shrinkage (Invited Talk). International Conference on Materials Science, Engineering & Technology, Singapore, 7-9 September 2022, Bogas JA, Carriço A, Real S.

Microstructural characterization of pastes produced with recycled cement. 9th International conference on sustainable solid waste management (CORFU2022), Corfu, Greece, 15-18 June 2022, Bogas JA, Carriço A, Tenza-Abril A.

Reducing the energy consumption for recycling cement: shifting from a wet method to an air-blowing method. 9th International conference on sustainable solid waste management (CORFU2022), Corfu, Greece, 15-18 June 2022, Sousa V, Bogas JA, Real S, Meireles I.

Recycled cement in more sustainable concrete – Towards green concrete. International conference on civil, structural and environmental engineering (CIVILMEET2022), Munich, Germany, 23-25 May 2022, Bogas JA, Carriço A, Real S.

Durability of concrete produced with recycled cement from waste concrete. 3rd International Congress on Materials & Structural Stability (CMSS 2021), Eco-Friendly Sustainable and Energy Efficient Materials & Constructions, Rabat, Morocco, 24-26 November, 2021. Materials Today Proceedings, 2022. Bogas JA, Carriço A, Real S.

Mechanical characterisation of concrete produced with recycled cement. 6th World Multidisciplinary Civil Engineering, Architecture, Urban Planning Symposium (WMCAUS 2021), Prague, Czech Republic, 31 August – 3 September, 2021. Bogas JA, Real S, Carriço A, Sousa V.

Carbon dioxide emissions of recycled cement production. 8th International conference on sustainable solid waste management (Thessaloniki 2021), 23-26 June 2021, Thessaloniki, Greece. Sousa V, Bogas JA, Real S, Meireles I.

Recycled cement thermoactivated at different temperatures. Proceedings of the fib symposium 2021, Concrete structures: New trends for eco-efficiency and performance, LNEC, Lisbon, Portugal, 14-16 June, 2021. Real S, Carriço A, Bogas JA, Guedes M.

Characterisation of the fresh and hardened properties of mortars produced with thermoactivated cement. Proceedings of the fib symposium 2021, Concrete structures: New trends for eco-efficiency and performance, LNEC, Lisbon, Portugal, 14-16 June, 2021. Carriço A, Real S, Bogas JA, Pereira MFC.

National conferences

Resistência à água de blocos de terra comprimida estabilizados com cimento reciclado termoativado (Water resistance of compressed earth blocks stabilized with thermoactivated recycled cement). Construção 2022, Universidade do Minho, 5 a 7 de Dezembro 2022.Cruz R, Azevedo B, Bogas JA, Real S.

Caracterização mecânica de blocos de terra comprimida estabilizados com cimento reciclado termoativado (Mechanical characterization of compressed earth blocks stabilized with thermoactivated recycled cement). Construção 2022, Universidade do Minho, 5 a 7 de Dezembro 2022. Real S, Azevedo B, Bogas JA, Cruz R, Carriço A.

Durabilidade de betões com incorporação cimento reciclado termoativado (Durability of concrete with recyced cement) 6as Jornadas Portuguesas de Engenharia de Estruturas. LNEC, Lisboa, Portugal, 9 a 11 Novembro 2022, Real S, Bogas JA, Carriço A.

Caracterização mecânica de betões com cimento reciclado termoativado (Mechanical characterisation of concrete with recyced cement) 6as Jornadas Portuguesas de Engenharia de Estruturas. LNEC, Lisboa, Portugal, 9 a 11 Novembro 2022, Carriço A, Bogas JA, Real S.

Absorção e retração de argamassas com cimento reciclado termoativado.( Absorption and shrinkage of mortars with recycled cement)IV simpósio: Argamassas e soluções térmicas de revestimento. ITECons, Coimbra, Portugal, 10 e 11 Março 2022, Carriço A, Bogas JA, Real S.

Cimentos reciclados termoactivados: estado de arte (Thermoactivated recycled cements: state of the art). Congresso Nacional Reabilitar & Betão Estrutural 2020 (BE 2020), LNEC, Lisboa, 3-5 November 2021, 11p. Carriço A, Bogas JA, Guedes M.

Evolução da hidratação e da microestrutura em pastas de cimento reciclado (Hydration evolution and microstructure in recycled cement pastes). Congresso Nacional Reabilitar & Betão Estrutural 2020 (BE 2020), LNEC, Lisboa, 3-5 November 2021, 11p. Carriço A, Bogas JA, Tenza-Abril J.

Argamassas de cimento reciclado: caracterização física e mecânica (Recycled cement mortars: physical and mechanical characterisation). Congresso Nacional Reabilitar & Betão Estrutural 2020 (BE 2020), LNEC, Lisboa, 3-5 November 2021, 11p. Real S, Carriço A, Bogas JA.

Caracterização mecânica de argamassas produzidas com cimento reciclado de baixo carbono termicamente reactivado (Mechanical characterization of mortars produced with thermoactivated low-carbon recycled cement). Encontro Nacional de Betão Estrutural (BE2018), LNEC, Lisboa, 7-9 November 2018, 10p. Bogas JA, Carriço A, Pereira MFC.

International conferences

MECHANICAL STRENGTH AND SHRINKAGE OF EARTH MORTARS STABILIZED WITH RECYCLED CEMENT

Balboa A, Bogas JA, Tenza-Abril AJ, Pérez-Hernándezd Y.

5º Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis

6-8 novembro, IST, Lisboa

ABSTRACT:

Earth has been used as a building material for thousands of years, allowing the development of different building techniques and materials, including earth mortars. In the last decade, earth building has become increasingly popular due to the new social awareness of sustainable development and also to the fact that earth as a building material has many advantages, both in terms of sustainability and in terms of comfort and health. However, low integrity and high susceptibility to water action are major disadvantages of earth building materials. Such problems can be minimized by stabilization. Ordinary Portland cement (OPC) is the most effective as stabilizer but its use is not sustainable due to its environmental impact. For this reason, the production of earth mortars with sustainable stabilizers such as low-carbon thermo-activated recycled cement (RC) and effective reuse of construction and demolition waste (CDW) is being explored. In this study, eight different compositions of earth mortars have been developed. Four of these were stabilized with OPC, three with recycled cement obtained from cement paste (RCP), and one without any stabilization. For all compositions, in the quest for sustainability, 25% of CDW was used to partially replace earth used in mortars. The incorporation of stabilizer was 12%, 16% and 20%. As the water requirement of RC is higher than that of OPC, one mortar with OPC with the same water content as that of RCP mortar was also produced for comparison purposes. The properties of the mortars were studied in terms of fresh (fresh density and consistency) and hardened (density, porosity, compressive and flexural strength, drying shrinkage) properties, up to 28 days.

Earth mortars stabilized with OPC showed better performance than those stabilized with RCP. These results are consistent with the higher water demand of RCP mortars, leading to higher porosity than those with OPC. The 28 days compressive strength of OPC mortars was found to be approximately 1.5 1.9 times higher than that of RCP mortars. However, it was found that the compressive strength for 12% RCP mortar was comparable to that obtained in reference OPC mortar with the same amount of water and binder. Moreover, the 28 days compressive strength of 12% RCP mortars were about 2 times higher than that of unstabilized mortars. In addition, mortars with RCP were found to show about 2 times higher 28 days shrinkage than those stabilized with OPC. However, a greater variability was observed in the shrinkage values of RCP mortars. Nevertheless, the results obtained in this study show that the addition of RCP improves the mechanical performance of earth mortars, being valid as stabilizer. Further research is needed to better understand the behaviour of RC in earth building materials.

RESULTADOS PRELIMINARES DE MORTEROS DE TIERRA ESTABILIZADOS CON CEMENTO RECICLADO: CARACTERIZACIÓN EN ESTADO FRESCO Y RESISTENCIA MECÁNICA

Balboa A, Bogas J, Tenza-Abril AJ, Pérez-Hernándezd Y.

XVII congresso Nacional de Materiales (CNMAT 2024), Málaga, Universidad de Málaga, Spain, 25-28 June 2024.

ABSTRACT:

La tierra se ha utilizado como material de construcción desde tiempos prehistóricos. En la actualidad, el uso de este material en el sector de la construcción está ganando popularidad debido a que empieza a plantearse como respuesta a la búsqueda y desarrollo de materiales y técnicas de construcción sostenibles, siendo un ejemplo de esto los morteros de tierra. Sin embargo, la tierra cruda presenta una baja capacidad mecánica y alta susceptibilidad frente a la acción del agua. Es por ello que se recurre a la estabilización. La estabilización con Cemento Portland Ordinario (OPC) presenta una gran efectividad, no obstante, su uso reduce la sostenibilidad de estos materiales a base de tierra. Por esta razón, se está explorando la utilización de estabilizantes con un menor impacto medioambiental como es el cemento reciclado termoactivado (RC), así como la adición de residuos de construcción y demolición (CDW) en morteros de tierra. Para ello, se han estudiado varias dosificaciones de morteros: i) estabilizadas con OPC; ii) estabilizadas con RC; y iii) sin estabilización. Los porcentajes de estabilizantes estudiados en ambos casos han sido del 12%, 16% y 20%. Además, el 25% de la tierra se ha reemplazado por CDW en todas las dosificaciones. Los morteros de tierra se han caracterizado en estado fresco (en términos de densidad y consistencia) y para edades de 3, 7 y 28 días, se ha caracterizado su resistencia a mecánica y velocidad de pulso ultrasónico. De forma general, a pesar de que los morteros de tierra estabilizados con OPC presentan un mejor comportamiento en términos de resistencia mecánica, los morteros de tierra estabilizados con RC también demuestran eficacia en la estabilización, ya que muestran una resistencia aproximadamente 2 veces mayor a de un mortero de tierra sin estabilizar. La velocidad de impulsos ultrasónicos es una técnica válida para evaluar las propiedades mecánicas de los morteros de tierra estabilizados con OPC y RC ya que presenta buenas correlaciones. Este estudio preliminar pone de manifiesto la necesidad de continuar estudiando el comportamiento de este tipo de estabilizante en los materiales de construcción a base de tierra.

ESTUDIO DE LA ABSORCIÓN CAPILAR Y RETRACCIÓN POR SECADO EN MORTEROS DE TIERRA ESTABILIZADOS CON CEMENTO RECICLADO

Balboa A, Bogas J, Tenza-Abril AJ, Pérez-Hernándezd Y.

XVII congresso Nacional de Materiales (CNMAT 2024), Málaga, Universidad de Málaga, Spain, 25-28 June 2024.

ABSTRACT:

En las últimas décadas, la tierra como material de construcción ha destacado principalmente debido a sus ventajas medioambientales, lo que ha promovido el desarrollo tanto de técnicas como de materiales a base de tierra, siendo un ejemplo de ello los morteros de tierra. Una de las desventajas más importantes de este material es su alta susceptibilidad a la acción del agua, que provoca tanto una disminución en su resistencia mecánica como en su capacidad de aislamiento térmico. Con la finalidad de reducir esta susceptibilidad se recurre a la estabilización. Aunque el estabilizante que otorga resultados más satisfactorios es el Cemento Portland Ordinario (OPC), debido a que este consume una gran cantidad de recursos naturales y es responsable de importantes emisiones de CO2 durante su producción, se están explorando alternativas que reduzcan el impacto ambiental, como el uso del cemento reciclado termoactivado (RC). El objetivo principal es estudiar la absorción capilar y la retracción por secado que se produce en morteros de tierra al utilizar RC para su estabilización, incorporando también un 25% de residuos de construcción y demolición (CDW) como reemplazamiento de tierra. Para ello, se ha estudiado la absorción capilar y la retracción por secado en diferentes dosificaciones de morteros donde la estabilización se ha realizado con OPC y con RC a una edad de 28 días. La cantidad de estabilizante en los morteros de tierra ha sido del 12%, 16% y 20%.

En general, los resultados demuestran la eficacia del uso de RC para estabilizar morteros de tierra frente a la acción del agua, ya que durante el proceso de absorción de agua evita su disgregación, al contrario de lo que sucede con aquellos sin estabilización. El coeficiente de absorción capilar se reduce a medida que el porcentaje de estabilizante adicionado aumenta. Los morteros de tierra estabilizados con OPC muestran menores coeficientes de absorción que aquellos que contienen RC. Aun así, los morteros de tierra con un 16 % y un 20% de RC tienen una absorción capilar comparable a los fabricados con un 12% de OPC. La retracción por secado de los morteros con RC es superior a los estabilizados con OPC. Se deben estudiar otras propiedades para comprender mejor el comportamiento de RC como estabilizador.

WATER RESISTANCE OF RECYCLED CEMENT COMPRESSED EARTH BLOCKS

Bogas JA, Cruz R, Azevedo B, Balboa A, Sousa V.

ABSTRACT:

In this study, low-carbon recycled cement (RC) was produced from thermally activated concrete and cement paste wastes and its incorporation in mortars, as cement replacement, was investigated. The calcination temperatures were defined based on thermogravimetric and X-ray diffraction analysis. Mortars were characterized in terms of their main fresh and mechanical properties (compressive and flexural strength, ultrasonic pulse velocity and dynamic modulus of elasticity). The influence of RC replacement ratio (20%, 50%, 75% and 100%), RC treatment temperature and RC fineness were analyzed. In all tested properties, RC from concrete waste showed significant lower efficiency than that from cement paste waste. The RC rehydration capacity was improved by increasing its fineness and preheating temperature. Mortars produced with 100% of 650 pre-heated RC were able to attain as high as 8.3 MPa of compressive strength at 28 days, corresponding to about 20% of that found in reference mortars without RC. In addition, mechanical properties were little affected by RC replacement ratios up to 20%. This study shows the efficient rehydration capacity of thermal activated RC and suggests its high potential for the construction industry.

THERMAL CONDUCTIVITY OF COMPRESSED EARTH BLOCKS PRODUCED WITH RECYCLED CEMENT

Gomes MG, Bogas JA, Real S, Cruz R

10th International Conference on Sustainable Solid Waste Management (CHANIA 2023), 21-24 June 2023, Chania, Crete, Greece.

ABSTRACT:

In the last decades, the growing concern with sustainability and the emergence of new construction techniques, namely mechanical and chemical stabilisation, to improve their performance and address some of their main issues (reduced water resistance), has brought a new momentum to earth construction (Riza et al., 2010). Chemical stabilisation of compressed earth blocks (CEB) is usually achieved with the incorporation of hydraulic binders, namely ordinary Portland cement (PC). Though it is effective in improving the overall performance of CEB (Walker, 2004; Riza et al., 2010), PC is a carbon intensive building material, associated with the consumption of large quantities of natural resources and energy, as well as, with the emission of copious amounts of carbon dioxide and other harmful green-house gases (Real et al., 2022).

Recently, a new promising binder has been developed as a more eco-efficient alternative to PC, thermoactivated recycled cement (RC), which is produced from recycled construction and demolition waste materials subjected to thermal activation at lower temperatures than PC (about 600-700ºC), thus, not only avoiding natural resource consumption and recycling waste, but also having reduced CO2 emissions during production (Real et al., 2022). RC has been successfully incorporated in other building materials, such as pastes, mortars and concrete (Real et al., 2020; Carriço et al., 2022; Real et al., 2021; Carriço et al., 2021). However, the effect of its use as a stabiliser on the performance of CEB has yet to have been assessed. Therefore, this study aims to analyse the influence of the incorporation of RC in the thermal conductivity of CEB. To this end, CEB were produced with different types of RC (recycled cement produced from cement paste waste treated at 650ºC) and PC and amounts of stabiliser (5-10%), as well as unstabilised CEB (UCEB). The tests were performed using through a modified transient pulse method (ASTM D5334, 2014; ASTM D5930, 2009), resorting to an ISOMET 2114 heat transfer analyser with a surface probe. The CEB were tested under varying moisture conditions, namely in laboratory conditions and in the dry and saturated states.

The thermal conductivity of the CEB in the saturated state was more than twice as high as those in the dry state, displaying a significant loss of thermal insulation capacity. In fact, the effect of the moisture content was more relevant to the thermal conductivity than other parameters, such as the type and amount of stabiliser. The CEB stabilised with RC displayed lower thermal conductivities than CEB stabilised with PC or UCEB. This should be due to the higher porosity associated to the CEB with RC, which were produced with a higher amount of water to account for the higher water demand and porosity of this stabiliser.

ABSTRACT:

Compressed earth blocks (CEB) is a technique that allows to improve earth performance, due to the action of high-pressure compaction, increasing the cohesion between particles and their bear strength (Cid-Falceto et al. 2012, González-López et al. 2018). In addition, to overcome the high variability and low integrity of earth, especially in humid environment, chemical stabilization is absolutely necessary (Mansour et al. 2016). In this regard, ordinary Portland cement (OPC) is the most efficient stabilizer, ensuring adequate mechanical and durability performance of CEB for an incorporation amount of 5-10% by weight of cement (Reddy 2012). However, the use of up to circa 200 kg/m3 of OPC significantly increases the embodied energy and environmental impact of CEB, eliminating the green nature of earth construction. In fact, the clinker production is responsible for over 7% of the CO2 world emissions (Sousa and Bogas 2021).

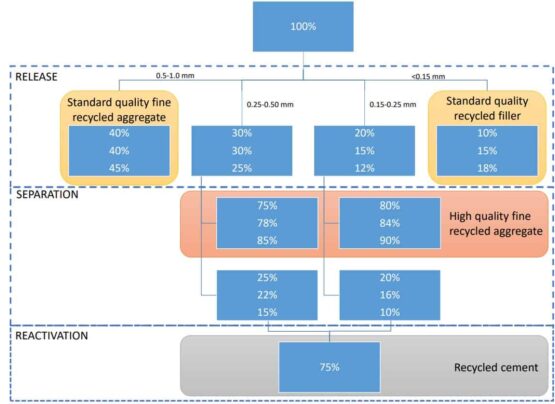

In this context, alternative low-carbon recycled cement (RC), retrieved from concrete waste, has been explored in Instituto Superior Técnico, University of Lisbon (IST-UL) during the last 4 years. The idea is to recover the binding properties of hydrated cement waste, through its thermoactivation at 600-700ºC (Carriço et al. 2020), and obtaining for the first time a hydraulic binder that is 100% recycled and 100% circular. RC directly contributes to the reduction of CO2 emissions, the saving of natural resources and the effective reuse of construction and demolition waste (C&DW). Moreover, it has been demonstrated the high rehydration capacity of RC and its comparable performance to OPC when incorporated in cement-based materials, namely in mortars and concrete (Carriço et al. 2020b, Bogas et al. 2020, Carriço et al. 2021).

Therefore, this study explores, for the first time, the use of RC as a more eco-efficient solution for CEB stabilization. In this case, CEB produced with different contents (5%, 10%) and types of stabilizer (100% OPC, 100% RC, and blended binders with partial replacement of OPC with 20% or 50% RC) were characterized in terms of their main physical and mechanical properties, namely density, compressive strength, splitting tensile strength, flexural strength, ultrasound pulse velocity, modulus of elasticity, pendulum sclerometer, elasticity modulus, shrinkage and thermal conductivity (Figure 1). CEB were characterized considering different curing (air and wet curing) and wetting conditions (dry, lab conditions, saturated). Unstabilized CEB were also considered for comparison purposes, allowing a better assessment of the potential contribution of RC as a stabilizer.

In general, for the analysed properties, although the performance of CEB decreased with the replacement of OPC with RC, the improvement was significant in relation to unstabilized CEB, especially in humid conditions. The lower performance of RC than OPC in stabilizing the CEB was attributed to the development of a lower amount of long-term hydration products and, especially, to the higher initial total porosity of CEB. The greater water demand of RC led to a higher amount of mixing water, increasing the water/binder ratio and the total porosity of CEB, which was up to 13% higher than that of OPC CEB. Therefore, under lab conditions of intermediate humidity, RC CSEB showed 25% less compressive strength and 24% less modulus of elasticity than reference OPC CSEB with equal amount of stabilizer. However, the reduction of compressive strength was less than 15% for up to 50% replacement of OPC with RC. A good correlation was found between compressive strength and other mechanical properties, showing the same trend regarding the influence of the type and amount of stabilizer. Long term shrinkage was lower in RC CEB of greater porosity and lower stiffness than in OPC CEB, but early shrinkage was similar in both CEB. The thermal conductivity was up to 26% lower in RC CEB due to their higher total porosity than OPC CEB. Under extreme saturation or drying conditions, the compressive strength reduction in RC CEB was 43% and 12%, respectively, underlying the lower stabilization capacity of RC than OPC.

Nevertheless, RC was an efficient stabilizer, leading to a significant improvement of tested properties, compared to unstabilized CEB. Stabilization with 10% RC was able to almost double the mechanical strength of unstabilized blocks, under lab conditions, and to ensure the integrity of CEB under saturation conditions, for a compressive strength over 2 MPa. Unstabilized CEB were highly sensitive to water, degrading fast after saturation.

THERMOACTIVATED RECYCLED CEMENT Towards fully-recycled net zero high sustainable green concrete (Invited Talk)

Bogas J.A.

Energy-Climate-Environment Conference ECE 2022 – Seminar “CCS-CCU technology for carbon footprint reduction using bio-adsorbents”, Czetochowa, Poland, September 14-16 2022

ECO-EFFICIENT GREEN MORTARS WITH RECYCLED CEMENT – MECHANICAL STRENGTH AND VOLUMETRIC SHRINKAGE (in

Bogas J.A., Carriço A., Real S.

International Conference on Materials Science, Engineering & Technology, 7-9 September, 2022, Singapore

ABSTRACT:

This study aims at characterizing the mechanical and shrinkage behaviour of mortars produced with different percentage replacement of Portland cement (PC) with Recycled cement (RC) retrieved from unrealistic lab-made old cement pastes (RCP) or directly obtained from hardened concrete waste (RCC). RCC was obtained from a new patented method of concrete waste separation, which allows recovering cement waste with circa 75 wt% purity. RCP was considered to better analyse the RC behaviour, without the influence of other contaminating constituents. Mortars were produced with bout 5, 15, 30, 50 and 100% RCP and up to 30% RCC. Due to the high RC water demand, they were designed with similar flowability or water/binder (w/b). Then, mortars were tested in terms of fresh properties (flowability, density), compressive strength, capillary absorption and drying shrinkage. Compared to reference PC mortars of equal w/b, the reduction of compressive strength in mortars with up to 100% RCP was lower than 25%. Moreover, the compressive strength was not significantly altered for up to 15% RCP. For the same consistency, mortars with RCP and higher w/b showed higher capillary absorption and higher shrinkage. However, for the same w/b, the absorption coefficient decreased with RCP content, because the interparticle porosity was lower than that of PC mortars. On the other hand, even for the same w/b, shrinkage increased with the replacement of PC with RCP. This was attributed to the denser interparticle microstructure of RC mortars and the higher porosity and lower stiffness of RC particles. Nevertheless, for up to 50% RCP, the 90 days shrinkage increased less than 17%. The replacement of the same amount of RCP with up to 30% RCC did not significantly affect the capillary absorption and slightly reduced compressive strength and long-term shrinkage. Overall, it was demonstrated the good efficiency of the new separation method and the high potential of RC as a supplementary cementitious material of high eco-efficiency.

MICROSTRUCTURAL CHARACTERIZATION OF PASTES PRODUCED WITH RECYCLED CEMENT

Bogas JA, Carriço A, Tenza-Abril A.

9th International conference on sustainable solid waste management (CORFU2022), 15-18 June 2022, Corfu, Greece

ABSTRACT:

The European commission have defined stringent targets regarding the reduction of greenhouse (GHG) gas emissions and the responsible generation, reuse and recycling of solid wastes (EC 2009). In this particular, concrete as the most used building material in the world, is the cause of significant GHG emissions, consumption of natural resources and generation of construction and demolition waste (CDW) (Schneider et al 2011). On the one hand, concrete waste represents over 30% of the CDW, which comprises the largest waste stream in Europe (Wang et al 2021). On the other hand, concrete production represents over 7% of the world man-made CO2 emissions, essentially attributed to clinker production (MPA 2021, Wang et al 2021). For this reason, the concrete industry and research community have been intensively exploring the development of more eco-efficient alternative binders and the reincorporation of CDW in building products, towards a more sustainable and circular construction practice CEMBUREAU 2020, Carriço et al 2020). Bearing this in mind, relevant research has been carried out regarding the production of recycled low-carbon binder from the hardened cementitious fraction of concrete waste. The idea is to recover the binding properties of cement waste through mechanical and thermal processing (Real et al 2021, Carriço et al 2021). Basically, the process involves one step of comminution (grinding and milling) followed by thermoactivation at low temperatures, in the range of 600-700ºC (Yu and Shui 2013, Carriço et al 2020). The manufacture of the obtained recycled cement (RC) may involves over 60% lower carbon emissions than conventional clinker, besides contributing to the lower depletion of natural resources and the greater valorization and reuse of CDW ( Sousa et al 2021). However, studies on this recent research domain are still limited. Most advances in this field have been essentially devoted to the production and mechanical characterization of cement-based materials produced with RC (Carriço et al 2020, Wang et al 2018). It has been demonstrated that the performance of RC may be greatly affected by the thermoactivated temperature (Yu and Shui 2013, Real et al 2020), and less by other factors such as the cooling rate and type of precursor concrete waste (Serpell and Zunino 2017, Carriço et al 2020). Depending on these factors and paste composition, the compressive strength of RC pastes may vary from as low as less than 10 MPa to as high as over 30 MPa (Wang et al 2018, Bogas et al 2019). So far, previous work of the authors have demonstrated that RC cam be comparable to low grade common Portland cement (PC) of class 32.5 (Carriço et al 2020b). Today, two major drawbacks on the industrial application of RC are its high water demand and difficult retrievement of the cementitious fraction from old concrete [Carriço et al 2020]. Regarding the later issue, the present Authors recently developed an innovative separation method able to individualize the cement fraction from other concrete constituents, with only up to 15% aggregate contamination, by volume (Carriço et al 2021b). A comprehensive review on the last findings regarding the production and application of RC is presented in Carriço et al (2020). Despite the significant research that have been carried out in this domain during the last 5 years, knowledge is still scarce, namely in relevant aspects, such as the hydration evolution, microstructure development, durability and volume changes of RC cement-based materials. Regarding the morphology and microstructure characterization of RC pastes, published studies are essentially limited to qualitative analysis based on scanning electron microscopy (Carriço et al 2020). Those studies have pointed out the apparent looser structure and long-term higher porosity of RC pastes compared to those with PC of equal composition. However, no comprehensive studies have been conducted regarding the detailed microstructural characterization of RC pastes. In this context, the present study discusses the microstructure of pastes with incorporation of RC retrieved from cement paste waste. For comparison purposes, reference pastes with common PC of the same workability were also analysed. All pastes were characterized in terms of mechanical strength, isothermal calorimetry, X-ray diffraction, thermogravimetry and microstructure (qualitative scanning electron microscopy, quantitative backscattering electron imaging, mercury intrusion porosimetry and nitrogen adsorption). The microstructure development was followed since early age, between 8 hours and 28 days. The combination of all aforementioned

techniques allowed a more reasoned microstructure characterization. In this study it is shown the rehydration capacity of RC, evidencing the development of hydration heat and the generation of common hydration products since early age, namely calcium silicate and calcium aluminate

hydrates. Contrary to PC, AFm phases are identified in RC pastes since 8 hours. However, Aft phases were less evident in RC pastes. The amount of carbonated phases tended to be higher in RC than in PC pastes. Hydration of RC progressed overtime, although at lower rate than PC. In fact, the volume of external hydration products at 28 days tended to be higher in PC pastes. RC pastes showed more refined porosity than OPC pastes of equal w/b, especially at early ages, until 3 days. However, the total porosity was similar. This is attributed to the biphasic microstructure of RC pastes, composed by the intraparticle porous structure and the interparticle space built by the outer hydration products. This led to a reduction f the water/binder ratio and a consequent densification of the outer space between particles. Although the mechanical strength of RC and PC pastes was similar up to 3 days, the 28 days compressive strength of RC paste was about 30% lower than that of PC paste.

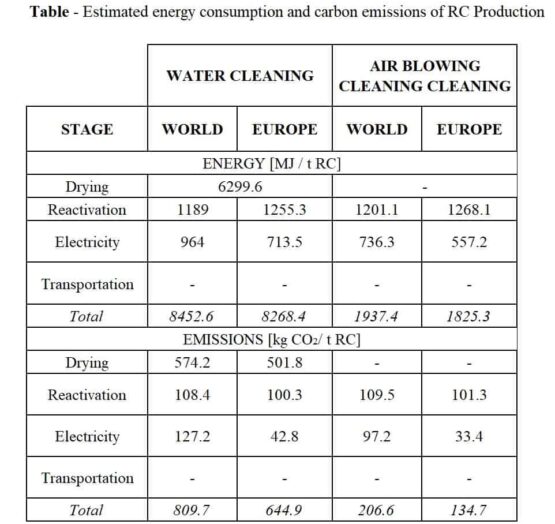

REDUCING THE ENERGY CONSUMPTION FOR RECYCLING CEMENT: SHIFTING FROM A WET METHOD TO AN AIR-BLOWING METHOD

Sousa V., Bogas J.A., Sofia R., Meireles I.

9th International conference on sustainable solid waste management (CORFU2022), Corfu, Greece, 15-18 June 2022

ABSTRACT:

Amongst the many challenges faced by mankind nowadays, excessive consumption of non-renewable resources and pollution are two of the most relevant. These two challenges are, in many cases, directly connected, with the consumption of non-renewable resources being, in most cases, also a source of pollution. One of such cases is the construction industry in general, and the concrete industry in particular. With an estimated consumption of over 30 billion tons per year, concrete ranks second in terms of the most consumed materials in the world after water (WBCSD 2009). This means that it is the most consumed artificial material worldwide, implying the consumption of large amounts of non-renewable resources in its production. In addition to the pollution during the production stage, concrete makes up a significant portion of the more than the 3 (Akhtar and Sarmah 2018) to 10 (Wu et al. 2019) billion tons of construction and demolition waste generated annually. The energy consumption of the cement industry represents 2% of global primary energy consumption or about 5% of total global industrial energy consumption (Hendriks et al. 1998). At the same time, the resulting carbon emissions makes cement production the third largest source of anthropogenic emissions of carbon dioxide (CO2), after fossil fuels and land-use changes, being responsible for 8% of the total emissions worldwide (Andrew 2018). Carbon emissions are, therefore, one of the most significant, if not the most significant, environmental impact directly associated with cement production and, indirectly, to the use of concrete (BIO 2011). Recycling cement from construction and demolition waste allows tackling both these challenges simultaneously by creating a closed-loop-recycling (ECRA 2017), contributing significantly towards the circular economy plan devised in the EU (EC 2020). In Europe, this solution would also contribute towards: i) meeting the goal of reusing, recycling or recovering a minimum of 70% (by weight) of non-hazardous construction and demolition waste, excluding naturally occurring material (article 11.2 of the Waste Framework Directive (EC 2008)); and ii) meeting the green deal targets (CEMBUREAU 2020) by the partial or total replacement of Portlant clinker by recycled cement (RC). This research effort builds on an ongoing research line carried out at IST, in particular the energy consumption necessary for RC production assessed by Sousa and Bogas (2021). The results obtained reveal that the need for washing and drying the material before separating the cement paste from the aggregates is responsible for the consumption of the largest portion of the total thermal energy required for producing recycled cement. As such, alternative solutions were explored to avoid the need for this washing and drying, namely by using air to remove the dust from the particles and increasing the power of the magnetic separator. The results presented in tTable reveal that the energy consumption of the RC air-blowing cleaning production method is roughly 25% of the RC wet cleaning production method and the emissions even less.

RECYCLED CEMENT IN MORE SUSTAINABLE CONCRETE – TOWARDS GREEN CONCRETE

Bogas JA, Carriço A, Real S.

International conference on civil, structural and environmental engineering (CIVILMEET2022), Munich, Germany, 23-25 May 2022

ABSTRACT:

Stringent targets have been defined by the concrete industry in order to reduce the greenhouse gas emissions, the concrete waste disposal and the excessive consumption of natural resources. Among other strategies, the reuse of concrete waste and the development of alternative cements have been focus of intensive research, towards more sustainable concretes. In this regard, relevant research have been carried out in the department of civil engineering of Instituto Superior Técnico, aiming the development of more eco-efficient concrete produced with recycled cement (RC) retrieved from hardened concrete debris. In the last decade various investigations have been conducted concerning the mechanical characterisation of pastes or mortars with RC obtained from laboratory cement waste pastes. However, the characterisation of concretes produced with recycled cement, as well as the retrievement of recycled cement directly from concrete waste, have been barely studied. This communication presents the recent findings on the production and behavior of concrete with recycled cement obtained from concrete waste (RCC) and from cement paste waste (RCP). RCC was obtained from the cement fraction of concrete waste according to a novel separation method patented by the authors. With this method, the cement fraction can be recovered with nearly 90 vol% purity. The consideration of RCP allows the more accurate analysis of the maximum potential of recycled cement. The concretes were characterised in terms of mechanical strength (compressive and tensile strength), modulus of elasticity, shrinkage, transport properties (oxygen permeability, capillary absorption), chloride migration and carbonation resistance. Concretes were produced with different w/b (0.35- 0.65), and 5 to 100% replacement of Portland cement (PC) with RC. In general, the mechanical strength was only little affected by the RC incorporation, showing a maximum strength reduction of only 17% for 100% replacement of PC with RC. Due to the high water demand of RC, the addition of super plasticizer (SP) greatly improved the RC efficiency. The addition of SP had a significant effect on the dispersion of cementitious particles and in improving the concrete compactness. Concrete with RC had comparable durability to that of PC concrete, regardless of the RC content. Durability and mechanical properties were more affected by the w/b than by the type of binder (RC or PC). Moreover, RC may refine the microstructure due to the reduction of the interparticle space. However, the total open porosity tends to be lower in PC concrete. A significant improvement was found in the mechanical and durability performance of RC concrete compared to that with the same content of non-treated concrete waste or commercial filler. RC proved to be a very effective supplementary material, reducing the carbon footprint of concrete without significantly affect their mechanical and durability proprieties. Concrete with RCC showed similar mechanical and durability behavior to that with RCP, for up to 30% incorporation. Concrete with only RC could be produced with strength class C25/30 and similar to higher durability of PC concrete of the same strength class. This indicates that 100% recycled concrete can be attained towards a truly circular economy of the concrete industry.

DURABILITY OF CONCRETE PRODUCED WITH RECYCLED CEMENT FROM WASTE CONCRETE

Bogas J.A., Carriço A., Real S.

International Congress on Materials & Structural Stability (CMSS 2021), Eco-Friendly Sustainable and Energy Efficient Materials & Constructions, Rabat, Morocco, 24-26 November 2021

ABSTRACT:

In the present study, concretes produced with recycled cement (RC) obtained from the thermoactivation of concrete waste (RCCW) or laboratory cement paste (RCPW) were analysed in terms of some of their main transport properties (capillary absorption, oxygen permeability) and carbonation and chloride penetration resistance. Recycled cement was incorporated at various percentages, between 5 and 100%, taking into account concretes of different w/b. RCCW was obtained from an innovative process of concrete waste separation recently patented by the authors, allowing the retrievement of cement waste with almost 90 vol% purity. RCPW and RCCW showed high rehydration capacity and concrete produced with them reached comparable durability to that of reference ordinary Portland cement (OPC) concrete. For up to 15% RCCW replacement the concrete durability was not significantly affected and the cement retrievement from concrete waste was very effective. Overall, RCPW and RCCW actively contributed to the densification of the microstructure and the improvement of concrete durability. The recycled cement, as obtained in the present study, showed high potential to be used as an eco-efficient clinker substitute.

MECHANICAL CHARACTERISATION OF CONCRETE PRODUCED WITH RECYCLED CEMENT

Bogas JA, Real S, Carriço A, Sousa V.

6th World Multidisciplinary Civil Engineering, Architecture, Urban Planning Symposium (WMCAUS 2021), Prague, Czech Republic, 31 August – 3 September 2021

ABSTRACT:

The concrete industry is currently facing the serious challenge of reducing its significant environmental impact, regarding the extensive extraction of raw materials, large generation of construction and demolition waste and relevant CO2 emissions. In this context, the low-carbon thermoactivated recycled cement (RC) has been emerged as a potential lever for the mitigation of these 3 vectors. However, due to the early stage of research in this domain, most studies have been only focused on the production of RC and its incorporation on cement pastes or mortars, without exploring its application in concrete production. In this study, it is characterized the mechanical behaviour of concrete produced with RC, either from waste cement paste or old concrete. To this end, a comprehensive experimental campaign involving the fresh, physical and mechanical characterization (compressive and tensile strength, modulus of elasticity) of concrete with RC and water/binder between 0.35 and 0.65 was carried out. It was found that the mechanical strength is little affected by the increase replacement of ordinary Portland cement (PC) with RC. Even considering 100% incorporation of RC, the mechanical strength was over 83% of that of the reference PC concrete with the same w/b. The incorporation of SP greatly improved the RC efficiency. Moreover, up to 15% incorporation of RC the mechanical strength of concrete was slightly improved, without either compromising its workability. From this study, it is shown the high potential of RC as an effective supplementary cementitious material. Up to 30% replacement, recycled cement directly retrieved from waste concrete according to a new patented method of the authors showed to be almost as effective as RC from waste paste.

CARBON DIOXIDE EMISSIONS OF RECYCLED CEMENT PRODUCTION

Sousa V, Bogas JA, Real S, Meireles I.

8th International conference on sustainable solid waste management (Thessaloniki 2021), Thessaloniki, Greece, 23-26 June 2021

ABSTRACT:

The cement industry is presently facing the demanding challenge of reducing its large amount of carbon emissions in order to meet the targets set to fight climate changes. One recent, and very promising, approach to reduce the carbon footprint is the production of more eco-efficient recycled cement from cement-based waste materials. This study aims at comparing the difference in terms of energy consumption and carbon dioxide emissions between recycled cement and conventional clinker production. The results demonstrate that overall carbon dioxide emissions, considering both direct and indirect emissions, of the recycled cement are 23% lower than the conventional clinker cement.

RECYCLED CEMENT THERMOACTIVATED AT DIFFERENT TEMPERATURES

Real S, Carriço A, Bogas JA, Guedes M.

Proceedings of the fib symposium 2021, Concrete structures: New trends for eco-efficiency and performance, LNEC, Lisbon, Portugal, 14-16 June 2021

ABSTRACT:

This paper discusses the effect of the thermal activation temperature on the rehydration of recycled cement and mechanical strength of pastes produced with this more eco-efficient binder. For this purpose, various tests were performed in order to characterise the thermoactivated recycled cement, namely thermogravimetry, X-ray diffraction, and 29Si nuclear magnetic resonance spectroscopy, as well as water demand, setting time and isothermal calorimetry. The mechanical strength of the recycled cement pastes was also determined. Overall, the dehydration and hydration of the thermoactivated recycled cement were significantly affected by the thermoactivation temperature, leading to the formation of distinct C2S polymorphs. The compressive strength of the thermoactivated recycled cement pastes was influenced by the different reactivity of these polymorphs. These binders presented longer setting times and their pastes displayed lower compressive strength than those with the reference CEM I. This was essentially attributed to the high water demand and pre-hydration phenomena exhibited by the thermoactivated recycled cement. The optimal thermal activation temperature was 700 °C.

CHARACTERISATION OF THE FRESH AND HARDENED PROPERTIES OF MORTARS PRODUCED WITH THERMOACTIVATED CEMENT

Carriço A., Real S., Bogas J.A., Pereira M.F.C.

Proceedings of the fib symposium 2021, Concrete structures: New trends for eco-efficiency and performance, LNEC, Lisbon, Portugal, 14-16 June 2021

ABSTRACT:

In this study, low-carbon recycled cement (RC) was produced from thermally activated concrete and cement paste wastes and its incorporation in mortars, as cement replacement, was investigated. The calcination temperatures were defined based on thermogravimetric and X-ray diffraction analysis. Mortars were characterized in terms of their main fresh and mechanical properties (compressive and flexural strength, ultrasonic pulse velocity and dynamic modulus of elasticity). The influence of RC replacement ratio (20%, 50%, 75% and 100%), RC treatment temperature and RC fineness were analyzed. In all tested properties, RC from concrete waste showed significant lower efficiency than that from cement paste waste. The RC rehydration capacity was improved by increasing its fineness and preheating temperature. Mortars produced with 100% of 650 pre-heated RC were able to attain as high as 8.3 MPa of compressive strength at 28 days, corresponding to about 20% of that found in reference mortars without RC. In addition, mechanical properties were little affected by RC replacement ratios up to 20%. This study shows the efficient rehydration capacity of thermal activated RC and suggests its high potential for the construction industry.

National conferences

CARACTERIZAÇÃO MECÂNICA E RETRAÇÃO DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM LIGANTES RECUPERADOS A PARTIR DA FRAÇÃO CIMENTÍCIA DE RESÍDUOS DE BETÃO

Cruz R, Bogas J, Nabais M, Real S.

5º Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis

6-8 novembro, IST, Lisboa

ABSTRACT:

A construção em Terra, mais concretamente a técnica de blocos de terra comprimida (BTC), ressurgiu nos últimos anos no sentido de atender à crescente preocupação ambiental por parte da sociedade. A estabilização dos BTC com cimento Portland (CP) é essencial para garantir o seu adequado desempenho a longo prazo, em especial na presença da água, porém é incompatível com a natureza ecológica e sustentável da construção em Terra. Como tal, tem existido um esforço de investigação relevante na procura de ligantes alternativos de baixo impacto ambiental para a estabilização química dos BTC. Neste sentido, no Instituto Superior Técnico (IST) tem sido explorada a utilização de cimento reciclado (CR) nos BTC. Para tal, foi realizada uma extensa campanha experimental que visou a produção e caracterização mecânica de BTC com diferentes teores e tipos de estabilizante, incluindo CR proveniente diretamente de pasta (CRP), CR a partir de detritos de betão (CRB) e ainda CP, como solução de referência. O CRB foi produzido tendo em conta um método recentemente desenvolvido e patenteado no IST. De modo a atingir soluções de maior eficiência foi ainda considerada a incorporação de até 25% de agregado reciclado resultante de resíduos de construção e demolição (RCD). Para efeitos de comparação foram também produzidos e caracterizados BTC não estabilizados, permitindo avaliar a eficiência do CR como agente estabilizante. No total, foram avaliadas 14 composições diferentes, incluindo a variação de diferentes parâmetros: teor de ligante (5%, 8%), taxa de substituição de CP por CRP ou CRB (20%, 50% ou 100%), tipo e/ou percentagem de agregado reciclado (0%, 15%, 25%), e teor de humidade (em equilíbrio com ambiente de laboratório, saturado, seco em estufa). Os blocos foram caracterizados em termos de massa volúmica no estado fresco e endurecido, resistência à compressão, resistência á tração por flexão e compressão diametral, dureza superficial por esclerómetro pendular, módulo de elasticidade, retração por secagem e velocidade de propagação dos ultrassons.

Em geral, os BTC estabilizados com CP apresentaram melhor desempenho nas várias propriedades analisadas do que os BTC com CR. Isso justifica-se pela menor compacidade atingida pelos BTC com CR após a sua produção. Porém, para igual compacidade, os resultados indiciam que o CR pode ser tão eficiente na estabilização dos BTC como o CP. A retração foi ligeiramente inferior nos BTC com CR do que com CP. Acrescenta-se que face aos BTC não estabilizados, a estabilização dos BTC com CR conduziu a resistências mecânicas até mais de 2 vezes superiores. Assim, conclui-se que a adição de CR é eficaz na estabilização química dos BTC, resultando na produção de blocos mais eco-eficientes sem grande prejuízo no desempenho técnico destes materiais. O CRB, recuperado de betão, foi igualmente eficiente, quando comparado com o CRP, demonstrando a boa eficiência do método de separação adotado no presente trabalho. A substituição parcial de solo por RCD teve uma influência pouco significativa na resistência mecânica dos BTC.

COMPORTAMENTO HIGROSCÓPICO DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM CIMENTO RECICLADO TERMOATIVADO

Real S, Bogas J, Cruz R, Gomes MG.

5º Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis

6-8 novembro, IST, Lisboa

ABSTRACT:

A estabilização de blocos de terra comprimida (BTC) com cimento reciclado termoativado (CRP) tem como objetivo a melhoria do desempenho mecânico e de durabilidade da construção em terra, sem comprometer de forma significativa a sua natureza ecológica e a suas propriedades térmicas. Neste estudo, analisou-se o comportamento higroscópico de BTC estabilizados com CRP, tendo sido comparado com o de blocos de terra não estabilizados ou estabilizados com cimento Portland (CEM). Para tal, foram determinadas as curvas de adsorção-dessorção de BTC considerando diferentes tipos de solo, tipos e quantidades de incorporação de estabilizante, tendo sido relacionadas com a sua microestrutura que foi caracterizada com base em microporosimetria de intrusão de mercúrio e adsorção de nitrogénio. A influência da estabilização nas propriedades higroscópicas dos BTC dependeu do tipo de solo. Dependendo do teor de argila, a estabilização pode aumentar ou reduzir a capacidade higroscópica dos BTC. O desempenho higroscópico dos BTC não foi afetado de forma relevante pela substituição parcial ou total de CEM por CRP. Assim, o CRP foi efetivo na estabilização dos BTC, tendo-se aproximado do comportamento mecânico e higroscópico dos BTC com CEM.

DESEMPENHO TÉRMICO DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM CIMENTO RECICLADO TERMOATIVADO

Real S, Bogas J, Cruz R, Nabais M, Gomes MG.

5º Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis

6-8 novembro, IST, Lisboa

ABSTRACT:

O presente estudo teve como objetivo a caracterização do comportamento térmico de blocos de terra comprimida (BTC) estabilizados com cimento reciclado termoativado (CRP) e com incorporação de resíduos de construção e demolição (RCD). Para tal, foi realizado um vasto trabalho experimental, em que foram analisadas as propriedades térmicas de BTC produzidos com diferentes tipos de solo, tipos e teores de estabilizante, e percentagens de incorporação de RCD. Dado que o desempenho térmico dos BTC é afetado pela sua microestrutura, estes também foram caracterizados em termos de microporosimetria de intrusão de mercúrio e adsorção de nitrogénio. As propriedades térmicas dos BTC foram essencialmente influenciadas pela sua porosidade global, e em segundo plano, pelo tipo e distribuição da porosidade, independentemente da sua composição. A condutibilidade térmica dos BTC foi afetada pelo teor de humidade, dependendo essa influência da distribuição de porosidade. Mesmo tendo em consideração BTC com idêntica porosidade total e resistência mecânica, a substituição de cimento Portland (CEM) por CRP ou de solo por RCD conduziram a melhor desempenho térmico. O comportamento térmico dos BTC com CRP ou CEM difere pela forma como estes estabilizantes afetam de forma diferente a sua microestrutura.

DURABILIDADE DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM LIGANTES RECUPERADOS A PARTIR DA FRAÇÃO CIMENTÍCIA DE RESÍDUOS DE BETÃO

Cruz R, Bogas J, Real S, Rodrigues J.

5º Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis

6-8 novembro, IST, Lisboa

ABSTRACT:

A técnica blocos de terra comprimida (BTC) explora a estabilização mecânica para melhorar o desempenho da construção em terra. Contudo, para garantir condições adequadas de durabilidade em ambiente exterior, a estabilização química é indispensável. Embora o cimento Portland (CP) seja o estabilizante mais eficaz e mais utilizado, é incompatível com a natureza ecológica e sustentável da construção em terra. Como tal, é urgente procurar estabilizantes alternativos de menor impacto ambiental, como é o caso do cimento reciclado (CR), recentemente desenvolvido no Instituto Superior Técnico (IST). Resumidamente, este ligante resulta da termoactivação a baixa temperatura de resíduos cimentícios recuperados de resíduos de betão e argamassa. A ideia é desenvolver soluções construtivas que envolvam apenas materiais naturais de baixa energia incorporada ou provenientes de produtos em fim de vida, como o CR e os resíduos de construção e demolição (RCD).

Assim, foi realizado um extenso trabalho experimental que teve por objetivo analisar a durabilidade de BTC produzidos com substituição parcial a total de CP por CR e solo por RCD. Consideraram se várias composições, envolvendo diferentes tipos de estabilizante (CP42.5, CP32.5, CR proveniente de pasta de cimento (CRP) ou de betão (CRB)), teor de estabilizante (0, 4% e 8%), percentagens de substituição de CP por CR (0, 20, 50 e 100%), teor de RCD (0, 15 e 25%) e teor de humidade (seco, saturado, em equilíbrio com o ambiente laboratorial). O CRB foi obtido através do método de separação recentemente desenvolvido no IST, alcançando purezas de cerca de 68% na fração cimentícia do betão. Os blocos foram caracterizados em termos de massa volúmica e resistência à compressão aos 28 dias, absorção de água por imersão, capilaridade e baixa pressão, permeabilidade ao vapor e erosão acelerada (drip test e spray test). Para efeitos de comparação foram considerados BTC de referência não estabilizados (NE) ou com incorporação de apenas CP.

Os BTC estabilizados com CR demonstraram resultados muito promissores, especialmente na redução da suscetibilidade à água. O comportamento dos BTC foi afetado pelo teor de ligante, teor de água de mistura e método de compactação. Os BTC com CP apresentaram melhor desempenho mecânico e menor absorção do que os BTC com CR, dado terem atingido maior compacidade. Porém, a erosão acelerada e a permeabilidade ao vapor não foram significativamente afetadas pelo tipo de ligante. A incorporação de RCD, até 25%, conduziu a soluções de maior compacidade e, como tal, melhores características mecânicas e durabilidade. Assim, a substituição parcial de solo por RCD é viável, conduzindo a soluções mais sustentáveis. Em contacto com água, os NE desintegraram-se totalmente após poucos minutos de imersão e erodiram-se em toda a sua espessura nos ensaios de erosão acelerada. No entanto, a estabilização dos BTC com CR permitiu que os blocos não sofressem dano após imersão, que atingissem a classe máxima de resistência à erosão acelerada e que triplicassem a resistência à compressão. Assim, conclui-se que o CR é uma alternativa viável ao CP.

RESISTÊNCIA À ÁGUA DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM CIMENTO RECICLADO TERMOATIVADO

Cruz R, Azevedo B, Bogas JA, Real S.

Construção 2022, Universidade do Minho, 5 a 7 de Dezembro 2022

ABSTRACT:

A necessidade de uma construção mais sustentável, assente em materiais de menor energia incorporada, faz com que ressurja o interesse na construção em terra. Os blocos de terra comprimida (BTC) são uma alternativa promissora, dado que permitem uma maior velocidade de processamento, menor variabilidade e maior resistência mecânica face a outras tecnologias de construção em terra. No entanto, a resistência à água é um dos maiores problemas dos BTC, sendo necessário proceder à sua estabilização. O cimento Portland (CP) é o estabilizante mais eficaz e mais utilizado, mas a sua incorporação na construção em terra é incompatível com a sua natureza ecológica e sustentável. Nesse sentido, no presente trabalho considerou-se a utilização alternativa de cimento reciclado (CR) de baixo carbono, obtido a partir da termoactivação de resíduos de materiais cimentícios, para estabilização dos BTC. Foram consideradas 7 composições, incluindo 3 misturas de referência (não estabilizada, e estabilizada com 5% ou 10% de CP, em massa), e BTCs com 20% 50% e 100% CR em substituição de CP, para 5% e 10% de ligante total. Os BTC foram caracterizados em termos da sua resistência à água, tendo em consideração ensaios de absorção por imersão, absorção capilar e de erosão acelerada por jato de água. Face aos BTC estabilizados com CP, a incorporação de CR reduziu a resistência à água. Porém, a estabilização dos BTC com CR foi adequada, conduzindo a uma melhoria significativa face aos BTC não estabilizados. Os BTC apresentaram elevada resistência à erosão acelerada, independentemente da composição do ligante.

CARACTERIZAÇÃO MECÂNICA DE BLOCOS DE TERRA COMPRIMIDA ESTABILIZADOS COM CIMENTO RECICLADO TERMOATIVADO

Real S, Azevedo B, Bogas JA, Cruz R, Carriço A.

Construção 2022, Universidade do Minho, 5 a 7 de Dezembro 2022

ABSTRACT:

A tendência atual de procura por materiais mais sustentáveis, reavivou o potencial de materiais de construção em terra. Por outro lado, dada necessidade de encontrar alternativas mais ecológicas aos atuais estabilizantes da terra, mais intensivos em carbono, como o cimento Portland (CP), têm-se procurado soluções alternativas de baixo carbono, como o cimento reciclado termoativado (CR). No presente estudo, pretende-se analisar o desenvolvimento de blocos de terra comprimidos (BTC) mais eco-eficientes, explorando a sua estabilização com a incorporação total ou parcial de CR em substituição de CP. Para tal, foram produzidos BTC com 5 a 10% de estabilizante e diferentes percentagens de incorporação de CR (20%, 50%, 100%) e caracterizados em termos de massa volúmica, resistência à compressão, resistência à tração por compressão diametral, resistência à flexão, módulo de elasticidade e velocidade de propagação de ultrassons. Em paralelo, foram também ensaiadas misturas de referência não estabilizadas ou estabilizadas com igual teor de CP. Os BTC foram ensaiados tendo em consideração diferentes condições de cura e de humidade, de modo a avaliar a eficiência das soluções estabilizantes preconizadas. Apesar de se verificar uma redução esperada das propriedades mecânicas face aos BTC com CP, verifica-se uma melhoria significativa face aos BTC não estabilizados, nomeadamente em condições de adversas de humidade. Assim, demonstra-se a viabilidade da produção de BTC estabilizados com CR, atingindo soluções mais sustentáveis.

DURABILIDADE DE BETÃO COM INCORPORAÇÃO DE CIMENTO RECICLADO TERMOATIVADO

Real S, Bogas JA, Carriço A

6as Jornadas Portuguesas de Engenharia de Estruturas. LNEC, Lisboa, Portugal, 9 a 11 Novembro 2022

ABSTRACT:

A necessidade de adoção de práticas mais sustentáveis na industria da construção conduziu ao desenvolvimento de novos ligantes mais ecológicos como alternativa aos ligantes intensivos em carbono correntes, nomeadamente os cimentos eco-eficientes de baixo carbono, como o cimento reciclado termoativado. Este estudo foca-se na caracterização da durabilidade de betão com incorporação de cimento reciclado termoativado obtido a partir de resíduos de pasta e resíduos de betão. Para tal, foram produzidos betões com uma relação água/ligante de 0,55 e diferentes percentagens destes novos ligantes de baixo carbono (5 – 40%), tendo sido caracterizados através de ensaios de absorção capilar, permeabilidade ao oxigénio, resistência à penetração de cloretos e resistência à carbonatação acelerada. O cimento reciclado termoativado apresentou uma capacidade de reidratação elevada, tendo, em geral, contribuído para a densificação da microestrutura e melhoria da durabilidade do betão. O betão produzido com incorporação de cimento reciclado termoativado atingiu uma durabilidade semelhante à de betão com cimento Portland.

CARACTERIZAÇÃO MECÂNICA DE BETÕES COM CIMENTO RECICLADO TERMOATIVVADO

Carriço A, Bogas JA, Real S.

6as Jornadas Portuguesas de Engenharia de Estruturas. LNEC, Lisboa, Portugal, 9 a 11 Novembro 2022

ABSTRACT:

Este estudo analisou a influência da incorporação de cimento reciclado (CR), resultante da ativação térmica de resíduos cimentícios, no comportamento mecânico de betões. O cimento reciclado foi obtido de pastas de cimento hidratadas e da fração cimentícia de betão recuperada através de um novo método de separação. Estes resíduos cimentícios foram posteriormente sujeitos a um tratamento térmico a temperaturas muito inferiores às necessárias na obtenção de clínquer a partir de matérias-primas tradicionais. Foram analisadas diferentes percentagens de incorporação de CR (0-40%) em substituição de cimento Portland. Os ensaios abrangeram a resistência à compressão, o módulo de elasticidade, a velocidade de propagação de ultrassons e a retração. De um modo geral, a resistência mecânica e a velocidade de propagação de ultrassons não foram significativamente influenciadas pela incorporação de CR. O módulo de elasticidade diminuiu e a retração teve tendência a aumentar para teores elevados de CR. Até 15% de incorporação o cimento reciclado obtido da fração cimentícia de betão apresentou um comportamento semelhante ao cimento reciclado obtido de pasta.

ABSORÇÃO E RETRAÇÃO DE ARGAMASSAS COM CIMENTO RECICLADO TERMOATIVADO

Carriço A, Bogas JA, Real S.

IV Simpósio: Argamassas e soluções térmicas de revestimento. 10 e 11 Março 2022, ITECons, Coimbra, Portugal

ABSTRACT:

O cimento reciclado (CR) é um novo ligante de baixo carbono obtido a partir da ativação térmica a baixas temperaturas de resíduos de materiais cimentícios hidratados. Este trabalho teve como foco a absorção e a retração de argamassas produzidas com CR proveniente de resíduos de pastas de cimento e betão de composição conhecida. Foram também analisadas diferentes percentagens de incorporação e a influência da finura e composição do material precursor. Adicionalmente, o efeito da combinação de cinzas volantes com CR em argamassas também foi analisado. Para tal, foram avaliadas as principais propriedades no estado fresco, a resistência à compressão, a absorção capilar e a retração por secagem. Devido à elevada exigência de água destes novos ligantes, foram produzidas argamassas de igual espalhamento e de igual a/c, para possibilitar a comparação em misturas de igual trabalhabilidade e de igual composição, respetivamente. Em argamassas de igual trabalhabilidade, os CR analisados neste estudo apresentaram uma exigência de água superior para atingir a fluidez pretendida, tendo-se verificado um crescimento linear com o aumento da percentagem de incorporação de CR. A mesma tendência foi observada em argamassas de igual a/c onde o espalhamento reduziu cerca de 100 mm nas argamassas com 50% CR face às argamassas de referência. A resistência à compressão de argamassas com 30% de CR de igual trabalhabilidade e igual a/c foi 70% e 90% da das argamassas de referência, respetivamente. Para 100% de CR verificou-se um decréscimo de 20% na resistência à compressão de argamassas de igual a/c. Para argamassas de igual composição, o coeficiente de absorção capilar das argamassas com 100% CR foi inferior ao das argamassas de referência. Para tal terá contribuído a natureza porosa das partículas de CR que, para um mesmo a/c, ao absorver parte da água de mistura permite que haja uma maior proximidade entre partículas adjacentes, contribuindo para a densificação da microestrutura. A retração por secagem das argamassas com CR foi superior à das argamassas de referência e principalmente influenciada pela menor dureza das partículas de CR e pelas ligações entre produtos de hidratação mais fracas do que as desenvolvidas numa matriz de cimento Portland Tipo I.

EVOLUÇÃO DA HIDRATAÇÃO E DA MICROESTRUTURA EM PASTAS DE CIMENTO RECICLADO

Carriço A, Bogas JA, Tenza-Abril J.

Reabilitar e Betão Estrutural 2020 (BE2020), Congresso Nacional – Lisboa, LNEC, 3-5 Novembro 2021

ABSTRACT:

O cimento reciclado (CR) é um novo ligante de baixo carbono obtido a partir da ativação térmica a baixas temperaturas de resíduos de materiais cimentícios hidratados. Este trabalho teve como foco a absorção e a retração de argamassas produzidas com CR proveniente de resíduos de pastas de cimento e betão de composição conhecida. Foram também analisadas diferentes percentagens de incorporação e a influência da finura e composição do material precursor. Adicionalmente, o efeito da combinação de cinzas volantes com CR em argamassas também foi analisado. Para tal, foram avaliadas as principais propriedades no estado fresco, a resistência à compressão, a absorção capilar e a retração por secagem. Devido à elevada exigência de água destes novos ligantes, foram produzidas argamassas de igual espalhamento e de igual a/c, para possibilitar a comparação em misturas de igual trabalhabilidade e de igual composição, respetivamente. Em argamassas de igual trabalhabilidade, os CR analisados neste estudo apresentaram uma exigência de água superior para atingir a fluidez pretendida, tendo-se verificado um crescimento linear com o aumento da percentagem de incorporação de CR. A mesma tendência foi observada em argamassas de igual a/c onde o espalhamento reduziu cerca de 100 mm nas argamassas com 50% CR face às argamassas de referência. A resistência à compressão de argamassas com 30% de CR de igual trabalhabilidade e igual a/c foi 70% e 90% da das argamassas de referência, respetivamente. Para 100% de CR verificou-se um decréscimo de 20% na resistência à compressão de argamassas de igual a/c. Para argamassas de igual composição, o coeficiente de absorção capilar das argamassas com 100% CR foi inferior ao das argamassas de referência. Para tal terá contribuído a natureza porosa das partículas de CR que, para um mesmo a/c, ao absorver parte da água de mistura permite que haja uma maior proximidade entre partículas adjacentes, contribuindo para a densificação da microestrutura. A retração por secagem das argamassas com CR foi superior à das argamassas de referência e principalmente influenciada pela menor dureza das partículas de CR e pelas ligações entre produtos de hidratação mais fracas do que as desenvolvidas numa matriz de cimento Portland Tipo I.

CIMENTOS RECICLADOS TERMOACTIVADOS: ESTADO DE ARTE

Carriço A, Bogas JA, Guedes M.

Reabilitar e Betão Estrutural 2020 (BE2020), Congresso Nacional – Lisboa, LNEC, 3-5 Novembro 2021

ABSTRACT:

O cimento reciclado (CR) é um novo ligante de baixo carbono obtido a partir da ativação térmica a baixas temperaturas de resíduos de materiais cimentícios hidratados. Este trabalho teve como foco a absorção e a retração de argamassas produzidas com CR proveniente de resíduos de pastas de cimento e betão de composição conhecida. Foram também analisadas diferentes percentagens de incorporação e a influência da finura e composição do material precursor. Adicionalmente, o efeito da combinação de cinzas volantes com CR em argamassas também foi analisado. Para tal, foram avaliadas as principais propriedades no estado fresco, a resistência à compressão, a absorção capilar e a retração por secagem. Devido à elevada exigência de água destes novos ligantes, foram produzidas argamassas de igual espalhamento e de igual a/c, para possibilitar a comparação em misturas de igual trabalhabilidade e de igual composição, respetivamente. Em argamassas de igual trabalhabilidade, os CR analisados neste estudo apresentaram uma exigência de água superior para atingir a fluidez pretendida, tendo-se verificado um crescimento linear com o aumento da percentagem de incorporação de CR. A mesma tendência foi observada em argamassas de igual a/c onde o espalhamento reduziu cerca de 100 mm nas argamassas com 50% CR face às argamassas de referência. A resistência à compressão de argamassas com 30% de CR de igual trabalhabilidade e igual a/c foi 70% e 90% da das argamassas de referência, respetivamente. Para 100% de CR verificou-se um decréscimo de 20% na resistência à compressão de argamassas de igual a/c. Para argamassas de igual composição, o coeficiente de absorção capilar das argamassas com 100% CR foi inferior ao das argamassas de referência. Para tal terá contribuído a natureza porosa das partículas de CR que, para um mesmo a/c, ao absorver parte da água de mistura permite que haja uma maior proximidade entre partículas adjacentes, contribuindo para a densificação da microestrutura. A retração por secagem das argamassas com CR foi superior à das argamassas de referência e principalmente influenciada pela menor dureza das partículas de CR e pelas ligações entre produtos de hidratação mais fracas do que as desenvolvidas numa matriz de cimento Portland Tipo I.

ARGAMASSAS DE CIMENTO RECICLADO: CARACTERIZAÇÃO FÍSICA E MECÂNICA

Real S, Carriço A, Bogas JA

Reabilitar e Betão Estrutural 2020 (BE2020), Congresso Nacional – Lisboa, LNEC, 3-5 Novembro 2021

ABSTRACT:

O presente artigo tem por objetivo a caracterização de argamassas produzidas com incorporação de cimento reciclado termoativado (CR). Para tal,

foi selecionada uma temperatura de tratamento de 700°C, de forma a obter adesidratação efetiva das partículas de CR sem descarbonatação significativa. Foi analisada a influência da percentagem de incorporação de cimento reciclado termoativado e da relação água/ligante na necessidade de água e tempo de presa do CR, bem como nas propriedades das argamassas no estado fresco e endurecido. A microestrutura e o desenvolvimento da hidratação foram analisadas tendo em consideração ensaios de termogravimetria, difração de raios-x, calorimetria e microscopia eletrónica de varrimento. A substituição de CEM I 42.5R por 20, 50 e 100% de CR permitiu atingir ligantes enquadráveis nas classes de resistência 52.5, 42.5 e 32.5, respetivamente. A elevada exigência de água é o principal obstáculo à aplicação do CR. No entanto, este aspeto assumiu menor importância para percentagens de substituição até 50%. A resistência mecânica foi pouco afetada ou diminuiu até cerca de 12% para percentagens de incorporação até 20% e 50%, respetivamente. Conclui-se que o CR é uma alternativa promissora face às atuais adições minerais utilizadas na indústria cimenteira.

CARACTERIZAÇÃO MECÂNICA DE ARGAMASSAS PRODUZIDAS COM CIMENTO RECICLADO DE BAIXO CARBONO TERMICAMENTE REACTIVADO

Bogas JA, Carriço A, Pereira MFC

Encontro Nacional de Betão Estrutural (BE2018), LNEC, Lisboa, 7-9 Novembro 2018

ABSTRACT:

O presente trabalho procurou caracterizar o comportamento de argamassas produzidas com diferentes percentagens de substituição de cimento Portland normal (CPN) por cimento reciclado proveniente de betão e pasta produzidos em laboratório, que foram sujeitos a um processo de moagem e subsequente queima a elevadas temperaturas. As temperaturas de calcinação foram definidas com base em análises termogravimétricas e de difração de raios X. As argamassas foram caracterizadas em termos das suas principais propriedades no estado fresco e endurecido (resistência à compressão e à flexão, velocidade de ultra-sons e módulo de elasticidade dinâmico). A influência da taxa de substituição por cimento Portland normal, CPN, por CR (20%, 50%, 75% e 100%), a temperatura do tratamento e a finura das partículas de CR, foram analisadas. Em todas as propriedades testadas, o CR dos resíduos de betão mostrou uma eficiência significativamente inferior à dos resíduos de pasta de cimento. A capacidade de reidratação do CR foi melhorada aumentando a sua finura e temperatura de pré-aquecimento. Argamassas produzidas com 100% de CR pré-aquecido a 650ºC atingiram 8,3 MPa de resistência à compressão aos 28 dias, correspondendo a cerca de 20% do obtido para argamassas de referência sem CR. Além disso, as propriedades mecânicas foram pouco afetadas por taxas de substituição com CR até 20%. Este estudo mostra a capacidade de reidratação eficiente do CR ativado termicamente e evidencia o seu elevado potencial para a indústria da construção.