Recycled Cement

Recycled cement (RC) is a new alternative low-carbon binder obtained from the thermal activation of cementitious waste materials at low temperature. The goal is to recover the binding properties of cement waste, closing the cycle by obtaining - for the first time - a fully recycled cement potentially produced in closed loop, towards a 100 % circular economy. With this new cement, required thermal energy is lowered and carbon emissions from burning may be reduced by over 60 %. The thermal load is less than half of that employed in traditional clinker manufacture, typically in the range of 600-800 ºC.

Considering all manufacture stages - concrete waste separation, gridding and thermal activation – it was found that RC production would save at least 30 % of the CO2 emissions currently associated with clinker production.

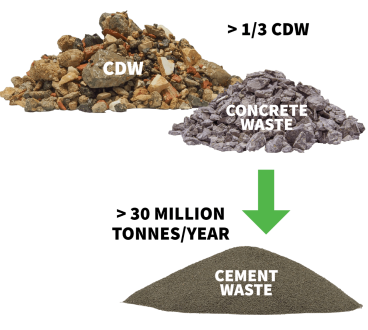

Besides the significant reduction of CO2 emissions, RC is a highly resource-saving material. The cement industry is

responsible for the consumption of about 1.5 tonnes of natural resources per clinker tonne (excluding fuels). These are spared through RC manufacture. Moreover, CDW comprises the largest waste stream in Europe, from which over 30 % is concrete waste. Therefore, RC also encourages

the high value reposition of CDW in new building products.

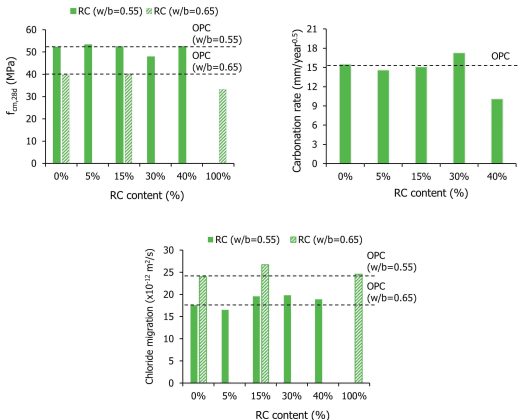

In the last years, various studies have been conducted and contributed to significant advances in this field, including those by the CDWvalue research team. These include the thermal optimization in RC production, and haracterisation of phase development, microstructure and fresh and hardened properties of cement-based materials with RC. Recycled cement at least comparable to low grade Portland cement class 32.5 has been attained. Moreover, the partial replacement of cement with up to 40 % RC have shown no significant change in concrete mechanical and durability properties. However, knowledge is still limited, and further research is needed. Currently, relevant studies are planned and others on track.

The production of recycled cement is also highly scalable, based on low-energy intensive procedures for the waste treatment and RC thermoactivation and fostered by the high availability of concrete waste. Considering over 800 million tonnes/year of CDW and about 1/3 of concrete waste, RC may potentially respond to a global demand of over 30 million tonnes/year of cement in Europe. This number is expected to further rise in the coming years, due to the increasing cement production and the more severe legislative measures regarding the CDW management.

Two research FCT projects are on track concerning the development of recycled cement (EcoHydB - PTDC/ECI-CON/28308/2017) and its incorporation in eco-efficient stabilized earth blocks (Eco+RCEB - PTDC/ECI-CON/0704/2021). Both count on the collaboration of various researchers from different institutions and industry partners.