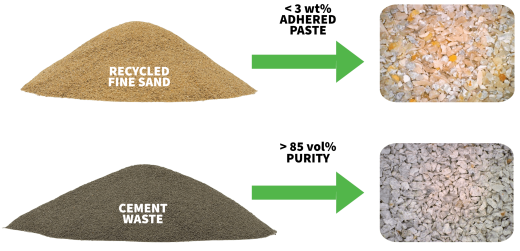

Recycled Sand

High-quality recycled sand (HQRS) with low amount of adhered paste can be produced according to a new patented separation methodology developed by the CDWvalue research team.

A main obstacle that has hindered the production of recycled aggregate concrete and recycled cement is the efficient retrieve of clean recycled aggregates and cement waste from concrete debris, especially at feasible cost and low environmental impact. Recently, the CDWvalue team developed a new patented separation procedure that is able to effectively separate the concrete constituents from each other. Through this process it has been possible to attain a cement fraction with aggregate contamination as low as 15 vol%, and a cleaner fine sand with less than 3 wt% of adhered paste.

The sand recycled from concrete waste is essentially composed of crushed siliceous and lime aggregate with 0.15-0.50 mm particle size and less than 3 % absorption. These characteristics are suitable for a range of applications in cement-based products (mortars, concretes, glue cements, plasters, etc.).

The production of HQRS is highly scalable, based on low-energy intensive procedures and on the high availability of concrete waste. Considering over 800 million tonnes/year of CDW and about 1/3 of concrete waste, RC may potentially respond to a global demand of about 200 million tonnes/year of sand in Europe, neglecting the contribution of other inorganic CDW materials. This is a relevant achievement, considering the increasing scarcity and environmental issues associated to the use of natural sand in the construction industry.